How To: Lubricant Dispensing and Transferring

Learning to properly dispense and transfer your lubricants is an essential skill for any maintenance professional. Following the correct process to complete this task is necessary to avoid contamination and keep your lubricants well organized.

Organizing Lubricants

When dispensing or transferring your lubricants, you can avoid cross contamination by labeling all containers. Color coding your containers with labels and tags can help you ensure lubricants are not mixed. Once your lubricants are labeled, you can color code equipment with a lubricant tag.

Choosing the Right Container

When choosing a container, do not use a galvanized container to transfer the lubricants. Using this container can cause zinc to leach into the lubricant or oil. Using clean sealed plastic containers and assigning one container per lubricant type will also help you ensure that no cross contamination occurs. This is where strong lubricant organization comes in handy.

Filtering

It’s important to remember to filter all lubricants that are put into your equipment. That goes for new oil as well! Just because it’s new doesn’t mean it’s clean. It should be filtered along with your other fluids. A lubricant filter cart should also be used when applicable.

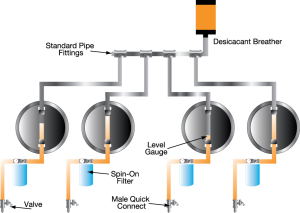

Rack Mount

Using a rack mount for your dispensing station is an effective tool to use for proper handling.

Choosing a dispensing container that was made for lubricant analysis is incredibly important. It is essential that the instruments you use to dispense and transfer your fluids are kept at the highest level of cleanliness and quality. To do otherwise is to welcome contamination into your fluids and your equipment.

To learn more about best practices for lubricant handling and storage, check out my recent blog posts on contamination and lubricant storage.

Proven Impact. Proven Uptime. Proven Savings.

Let us prove it to you.