Don’t Delay When it Comes to Your Fuel Reports

Read Your Reports

Read your analysis reports as soon as you get them. If you took the time to test your fuel that means you’re trying to avoid an issue (clogging fuel filters, injector warranties) or you’re looking to troubleshoot problems you’re experiencing (lack of power, fuel quality concerns). Don’t wait until it’s too late before you evaluate your report results – failure can occur at any moment.

Review the Test Data

On analysis reports, test values that have diagnostic significance will be flagged or highlighted in some way (boldface type, color coded, etc.). You should begin your review with analyzing these flagged results.

Review each test value individually and then look for coordinating data that can help confirm the analysis. Knowing your test properties will help tremendously with understanding the test results. If you’re unsure or need help interpreting results, you can contact the laboratory for more explanation. A quality, dependable laboratory will spent the time helping you understand the analysis.

Analyze the Analyst’s Comments

After reviewing the data, it’s then time to look at the data analysts’ comments. Many laboratories set the overall severity based on the analyst’s interpretation of the results, rather than one single severe reported limit. The comments will outline the wear patterns, if applicable, then the condition of the fluid. These comments can also include sources of contamination and recommended maintenance actions.

Ensure Sample Information Accuracy

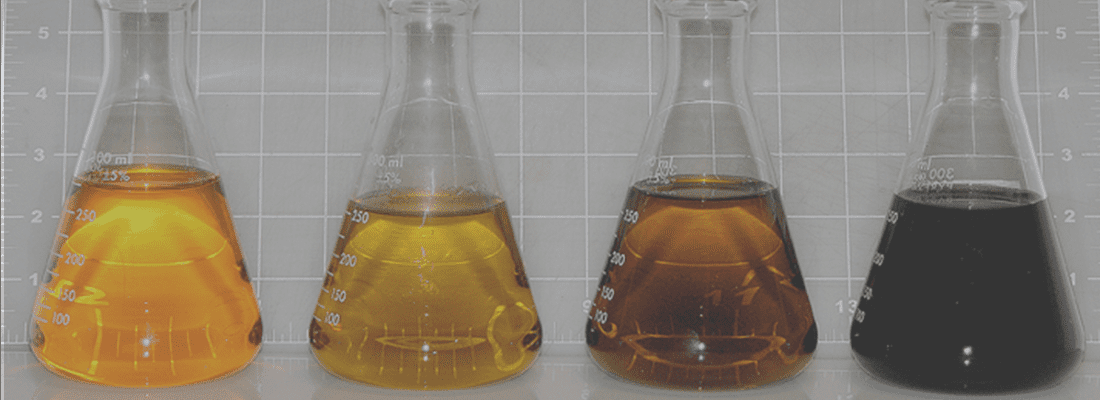

If incomplete information was provided for the sample, the analysts cannot provide a quality and effective analysis of your fuel. Simply submitting the sample as “diesel fuel” limits the analysis because there are different grades of diesel fuel (ULS #1, #2) and each have separate ASTM alarm limits. If needed, contact the laboratory to provide updated information and then ask for a re-evaluation of the sample.

Provide Feedback to the Laboratory

Feedback on test results and maintenance actions provided to the laboratory is crucial to effectively understanding and managing your fuel program. Laboratories test your fuel with the intention of providing you with accurate, reliable and timely results so you can maximize your Return Of Investment (ROI) of your program. In order for the laboratory to help improve your program, it’s important to open the lines of communication when it comes to results and actions taken by your team.

Proven Impact. Proven Uptime. Proven Savings.

Let us prove it to you.