Monitoring equipment, component and lubrication conditions through routine fluid analysis allows you to avoid unplanned downtime and perform necessary maintenance based what is actually happening within the unit rather than on the hours in operation, miles traveled or calendar days.

Uptime Isn’t Optional: Back It with Fluid Analysis

For mission-critical power generation, backup systems and data centers, equipment uptime is not optional, it’s required.

A Silent Shield: Protect Mission-Critical Assets

To monitor component and fluid health, natural gas generators, hydraulics and standby generators need routine fluid analysis testing. Wear and tear can happen inside the equipment and, without warning, can cause serious, costly downtime for your operation, and your customers.

WEBINAR:

Zero Tolerance for Downtime: Fluid Analysis for Critical Power Systems

Tuesday, February 10, 2026 | 11 a.m. ET

Unplanned downtime in power generation and data center environments can be costly and disruptive. Fluid analysis plays a critical role in monitoring equipment health, identifying developing issues, and supporting predictive, data-driven maintenance decisions.

In this webinar, our in-house subject matter expert, Mel Prieve, will focus exclusively on the power generation and data center industry, sharing practical insights into how oil, coolant, and diesel fuel analysis can be used to improve reliability, extend equipment life, and protect uptime for both prime, data centers and backup power systems.

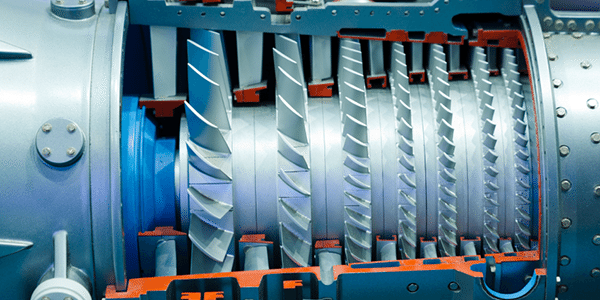

How to Ensure Optimum Performance of Wind Turbines

The operating fluids inside a turbine, including lubricating oil in gearboxes and hydraulic systems, fluids used in cooling systems and greases all play a significant role in optimizing operation of the wind turbine. All these operating fluids should be monitored closely to determine the condition of the fluid, identify contamination and measure the levels of wear metals…

Addressing Silicon Levels with Micropatch Testing to Extend Drains in Gas Engines

Check out how one power generation customer utilized micropatch testing to better understand the condition of their oil, and with close monitoring and regular sampling, has extended the oil drain interval from a weekly change of around 150 hours, to an operating time of 650 hours on average.

The Power to Predict Failures

Dramatically reduce unscheduled shutdowns and give your maintenance program the power to predict failure. Contact our team today to get started protecting your most valuable assets.