POLARIS Laboratories® has the practical tools available to simplify sample retrieval and help you get the most out of your data. Utilizing a sampling device ensures a clean, uniform sample and more precise results, giving you the confidence to quickly respond to changes in system conditions. An ideal sample will reflect the oil’s state as it is with regular equipment operation and is easy to achieve with the right plan and tools in place.

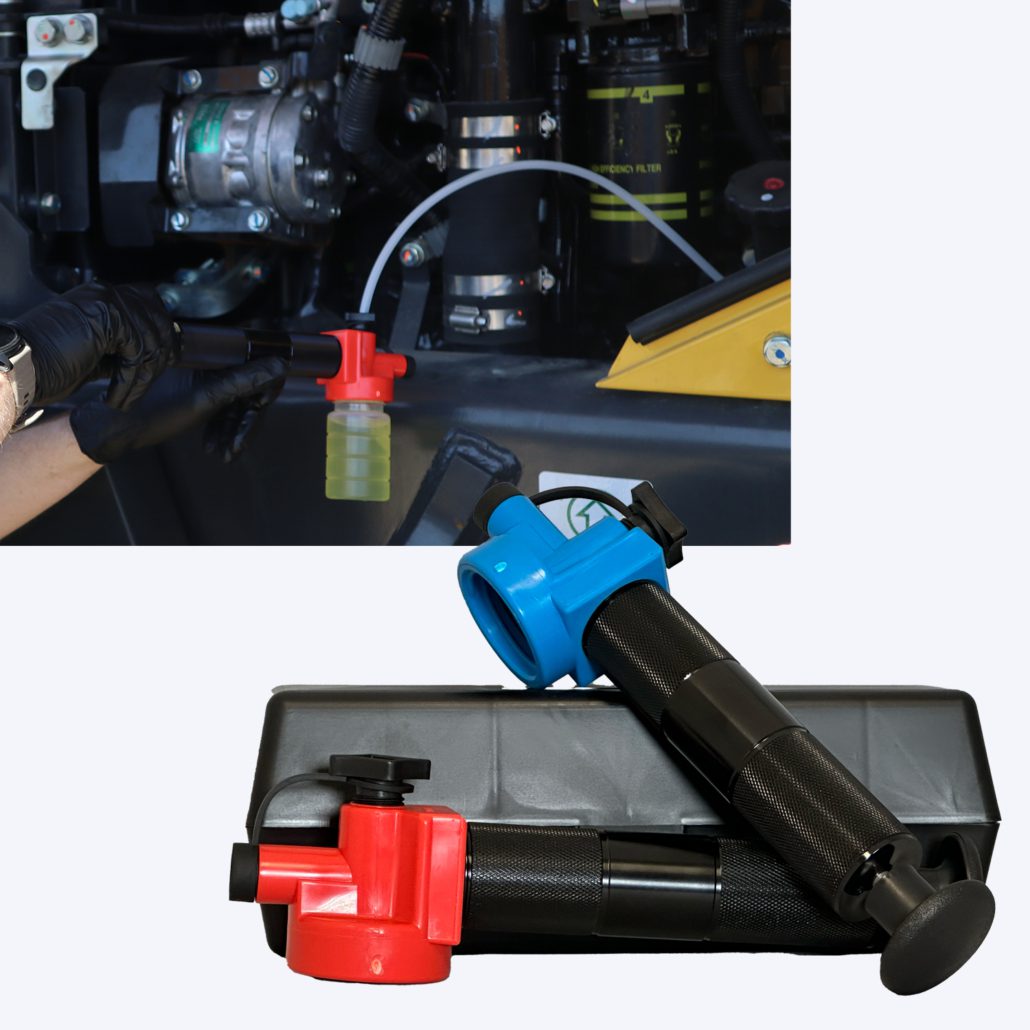

Vacuum Pump

While taking a sample from the drain may be quick, there is an increased likelihood of capturing settled debris from the bottom of the sump, impacting your sample results. A vacuum pump and proper-sized tubing allow fluid extraction from the data-rich zone of the equipment’s reservoir while avoiding unwanted sludge or debris that may skew the analysis. Once the extraction procedure is mastered, a high-quality sample can be taken in minutes. Two color options (red or blue) are available for easy visual identification to prevent cross-contamination between oil or cooling systems.

Sample Valves

Accurate, reliable, and timely fluid analysis results are vital to maintaining equipment performance and longevity. Sample valves are the next step in achieving convenient, consistent, reliable sample results. Sampling from a fixed location provides representative oil from the system, minimizes contamination risk, and offers flexibility for targeting specific system components to identify wear and contaminants. Plus, installing a valve is relatively easy and saves time and labor. With the associated cost savings, valves typically pay for themselves in under a year, and the long-term savings continue to compound throughout their lifetime. Reliability, sampling speed, and ease of use make sample valves the clear go-to option for all maintenance professionals.

Pushbutton Valve

The pushbutton style sample valve boasts a rugged, corrosion-resistant design and utilizes a reliable, easy push-to-open and release-to-close action. No probes are required for sampling, making this a cost-effective option for pulling samples. The 360° rotating spout allows convenient sampling and installation without additional parts or supplies and includes a protective screw cap to keep out debris when not in use. Pushbutton valve models are available for sampling both high (up to 750 psi) and low-pressure applications and are suitable for a variety of different equipment types.

Probe Valve

Probe-style valves are equipped with vacuum-tight seals ideal for sampling in dusty or contaminant-prone environments. A unique cap and tubing with a (standard 2 mm) needle probe are used to carefully extract a clean sample without opening the sample bottle. This significantly reduces the risk of introducing foreign debris and environmental contaminants, whereas the metal screw cap protects the sample port when not used. Probe-style valves offer a low purge volume, higher flow for low-pressure applications, and dynamic sampling (up to 750 or 4000 psi with a specialized probe) and are manufactured with environmentally friendly plating.

High Flow Valve

High-flow sample valves are designed with low-viscosity oils in mind. Like the probe-style valve, the high-flow valve uses a special probe with a broader opening to extract more viscous oils at lower pressure (125 psi or under). The flat face surfaces are easy to clean, and the compact design and sealed cap also make them ideal for low clearance zones. High-flow valves come in a variety of specifications, including a variety equipped with metal tubing for reaching active gearbox zones or a mobile drives-specific model replacing traditional drain plugs for hassle-free installation. Several probe designs from a barbed needle, quick-connect, and more create options and flexibility to suit your needs.

Sample valves and associated equipment can be ordered via the HORIZON online store at www.eoilreports.com. Select the location to receive the valves and navigate to the “Supplies” tab. Valve orders can be placed along with kits, tubing, and other supplies but will be shipped separately.

If you have questions about which valves to order, contact our Customer Experience team at custserv@eoilreports.com or 317.808.3750 for more information.