Seeing the Unseen: Advancing Microscope Wear Analysis

At POLARIS Laboratories®, precision and innovation drive everything we do, especially when it comes to helping customers understand what’s happening inside their equipment. We’ve recently expanded our analysis capabilities with the addition of the Olympus DSX1000 Digital Microscope, a powerful tool that enhances our ability to detect, analyze, and document wear debris consistently across all our global laboratories – something you won’t get with other laboratories.

Elevating Microscopic Analysis Capabilities

The Olympus DSX1000 delivers unmatched magnification, clarity, and automation, allowing our data analysts and reliability experts to visualize the smallest wear particles with extraordinary detail. With up to 9,637x magnification, this technology captures what traditional microscopes can miss and gives customers a more complete picture of component wear and overall fluid cleanliness.

The advanced microscope allows for consistent, high-resolution imaging across every sample we test and analyze. This automation not only speeds up analysis time but also ensures repeatability and accuracy, both critical factors when trending wear patterns or investigating abnormal test results.

Connected Technology & Global Consistency

Thanks to its PRECiV unified imaging software, the DSX1000 seamlessly connects every POLARIS Laboratories® location worldwide. Samples can be scanned with the microscope at our headquarters laboratory in Indianapolis and reviewed and interpreted by reliability analysts at any of our seven global laboratories. This feature enables remote collaboration, faster training, and a consistent interpretation of results across the globe.

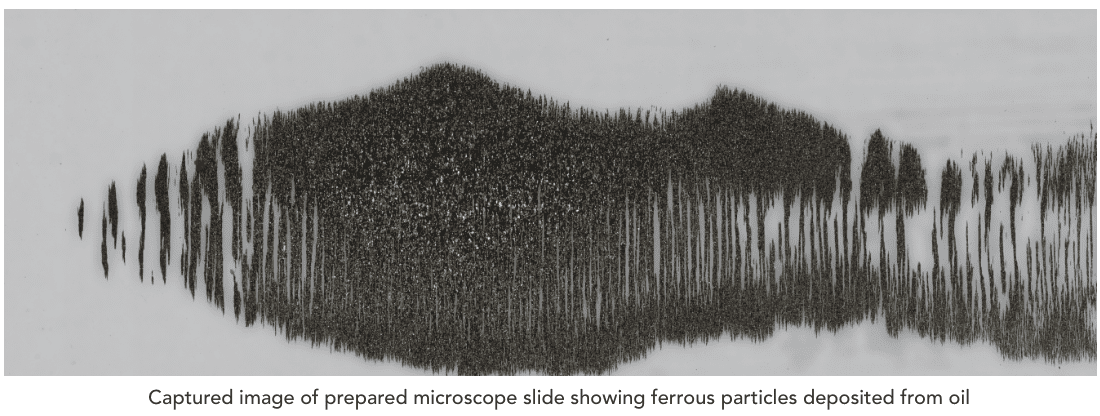

This connectivity also supports global standardization in testing methods like Analytical Ferrography, Micropatch, and Photomicrograph Analysis. Customers benefit from the same advanced imaging, precision, and reliability, no matter which lab processes their samples.

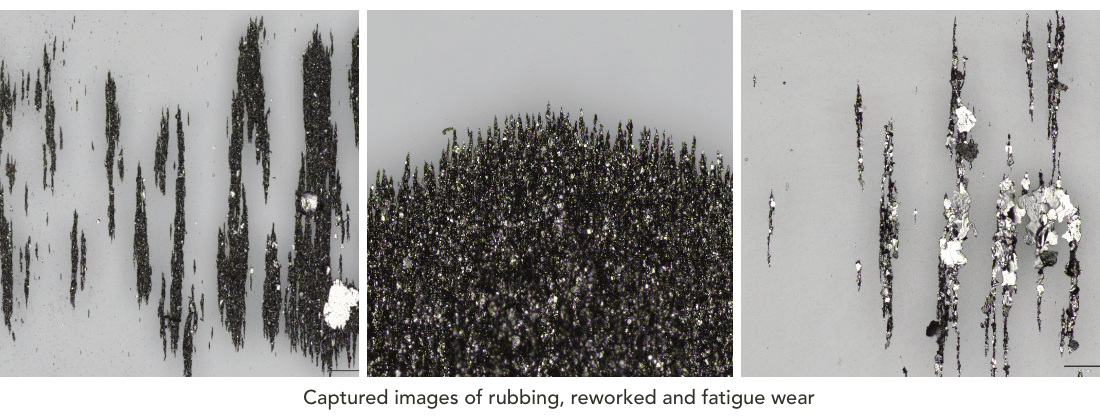

Beyond the Numbers: Telling the Story

While fluid analysis provides the data, microscopic analysis tells the story. The DSX1000’s multiple observation modes, like Brightfield, Oblique, Darkfield, Mixed, and Polarization, help analysts reviewing the images distinguish between particle types, identify ferrous wear, and investigate sources and failure modes. This level of detail allows for more accurate root cause analysis (RCA), helping customers make confident maintenance decisions based on clear, visual evidence.

The result? Earlier detection of wear, more reliable diagnostics, and greater confidence in making critical decisions.

Raising the Bar for Reliability

By integrating this advanced microscope technology into our global operations, POLARIS Laboratories® continues to lead the industry in delivering data you can trust and insights you can act on. The DSX1000 doesn’t just enhance our testing capabilities, it strengthens the connection between the laboratory and your maintenance team, helping you protect assets, extend component life, and improve overall equipment reliability.

Published November 13, 2025