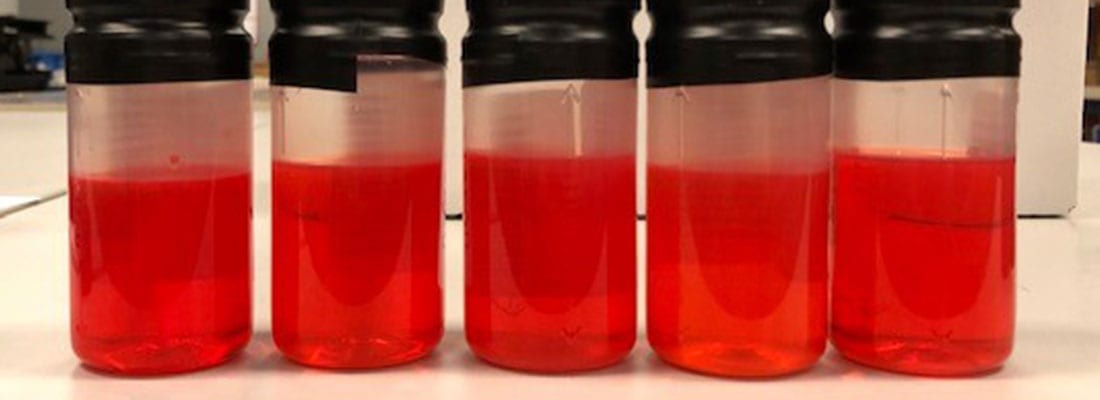

Appearance May Not Tell the Whole Story

Appearances can be deceiving! During every PM you need to be monitoring your cooling system.

Your coolant should be clear of precipitate and have the appearance of new fluid when first put into the system. However, only monitoring the appearance may not tell the whole story of the health of the cooling system. Appearance can indicate some concerns when an odor or clarity change occur. However, with further testing performed at regular PM intervals, in conjunction with laboratory testing to monitor the health of the cooling system, concerns can be caught earlier rather than just monitoring the appearance.

Some early system concerns that will not be visible by just looking at your coolant:

- Corrosion

- Hard water contamination

- Chemical reaction impacting pH levels

- Inhibitor levels

- Degradation due to overheating

- Glycol concentration for adequate freeze point and boil point control

Utilizing proper testing to monitor the cooling system and fluid health are very important for maintaining your equipment.

The cooling system is critical to maintaining proper temperature for the equipment. Approximately 40 to 50 percent of preventable engine failures can be traced back to problems in the cooling system. Of those failures due to the cooling system, 80 percent of the concerns can be identified and corrected early before attributing to engine concerns leading to an unnecessary failure. Proper testing will detect problems that are not visible to the naked eye and determine if the cooling system is able to protect your equipment and prevent unexpected equipment down time and increase maintenance costs.

Proven Impact. Proven Uptime. Proven Savings.

Let us prove it to you.