Case Study: Filter Debris Analysis

Identifying the Root Cause of Problems with Filter Debris Analysis

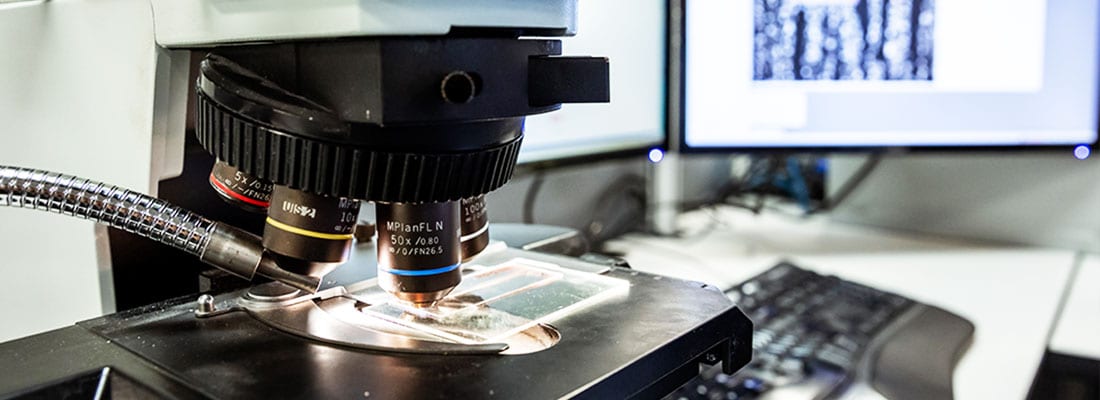

Routine fluid analysis can help to monitor equipment conditions and extend component life. But, by going the extra step and performing Filter Debris Analysis, and other tests to analyze particles found within the filter, you can identify harmful debris, identify the root cause of the problem and save the replacement costs.

Filter Debris Analysis, Analytical Ferrography and Micropatch testing was performed on one customer’s sample and the results were able to help identify the root-cause of consistent failure of a gearbox. Learn how this POLARIS Laboratories® customer was able to save more than $250,000 by performing the testing.

Seeing The Savings

- Cost of Filter Debris Analysis, Micropatch and Analytical Ferrography testing: ~$500

- Savings earned by saving the gearbox component: $250k

- Return on Investment achieved: 500:1