Sampling Devices: Find the Right One for Your Program

Sampling devices are used to pull samples of lubricant, coolant or fuel out of system components. There is a range of sampling devices to fulfill specific needs, but they can be grouped into two basic categories – 1) vacuum pumps and 2) installed sampling devices.

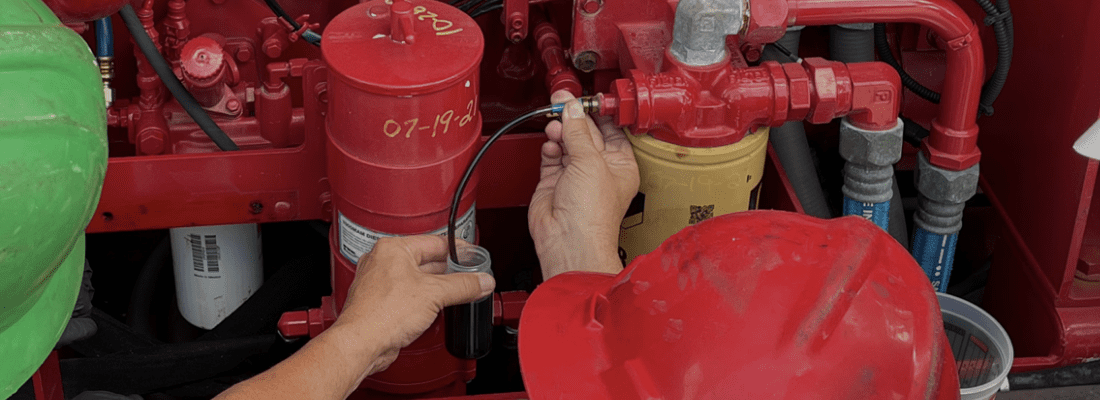

Vacuum Pumps

vacuum pump

Vacuum pumps pull fluid from a component’s reservoir. Disposable tubing is fed through the pump and into a sample jar screwed onto the pump. The other end of the tubing is used to reach into the component’s reservoir. The vacuum from the pump pulls fluid out of the reservoir and into the sample jar without contacting the pump itself. Oil residue in the tubing would contaminate future samples, so it must be thrown away. The pump itself never touched the fluid and can be reused without cleaning.

Installed Sampling Devices

Commonly referred to as “valves,” small sampling devices are installed on components to create a permanent, easily accessible port for drawing samples. Using valves to pull fluid is typically faster than using vacuum pumps alone. The valves also minimize the chances of environmental contamination entering the sample or the fluid system. These permanent devices collect the most representative samples possible in the least amount of time. The two most common types differ based on if the system is pressurized or not.

Push Button (4-100 PSI) – Pushing a button on the device opens the port. The pressure from the system pushes fluid through the port and into an open sample jar held below the valve.

push button valve

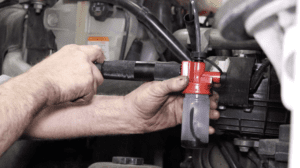

Push Pin (4-1000 PSI) – Inserting a “pin” or “needle” into the device opens the port. System pressure or a vacuum pump moves fluid through tubing attached to the pin. A cap is screwed onto the sample jar to secure the other end of the tube when a vacuum pump isn’t used. The pin, tubing and cap cannot be easily cleaned and must be thrown away.

push pin valve

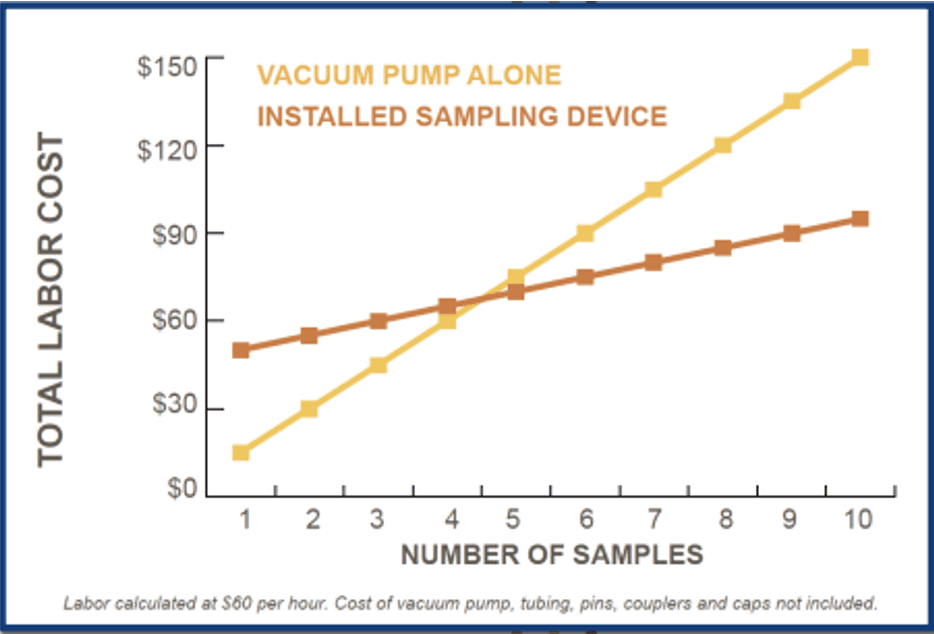

Installed Sampling Devices Save Time And Money

One vacuum pump can draw samples from multiple components, but it pulls samples slower than an installed sampling device. Generally, the reduced sampling time pays for the device and its installation after five samples.

So what are you waiting for? Order your sampling devices (i.e. Push Button or Push Pin) via the HORIZON Store, install them as soon as possible to start saving even more money with your fluid analysis program!

Maximize asset reliability and regain control of your production schedules with an effective fluid analysis program by POLARIS Laboratories® . . . it costs so little to protect so much.

Proven Impact. Proven Uptime. Proven Savings.

Let us prove it to you.

Published March 16, 2023