VIDEO: How to Bridge the Gap with Filter Debris Analysis

Oil filters are designed to remove contaminants and particles that would have otherwise damaged the system – but did you know this also removes the evidence that data analysts can use to provide in-depth maintenance recommendations? Dive deeper into the particles, contamination and evidence of wear that are caught in the oil filter by sending in your oil filter for Filter Debris Analysis.

FDA Dives Deeper Into Contamination Causes

Standard oil analysis (Elemental Analysis by ICP) can provide you with information on what’s going on in your equipment – but, there are limits to what ICP can detect. ICP can only detect fine particles of approximately 10 microns or smaller – leaving larger particles unidentified. Filter Debris Analysis helps identify larger wear particle debris as well as outside contamination. The wear morphology, metal type(s) and contamination types can be identified to help determine the possible source of the wear or contamination.

How is FDA Performed?

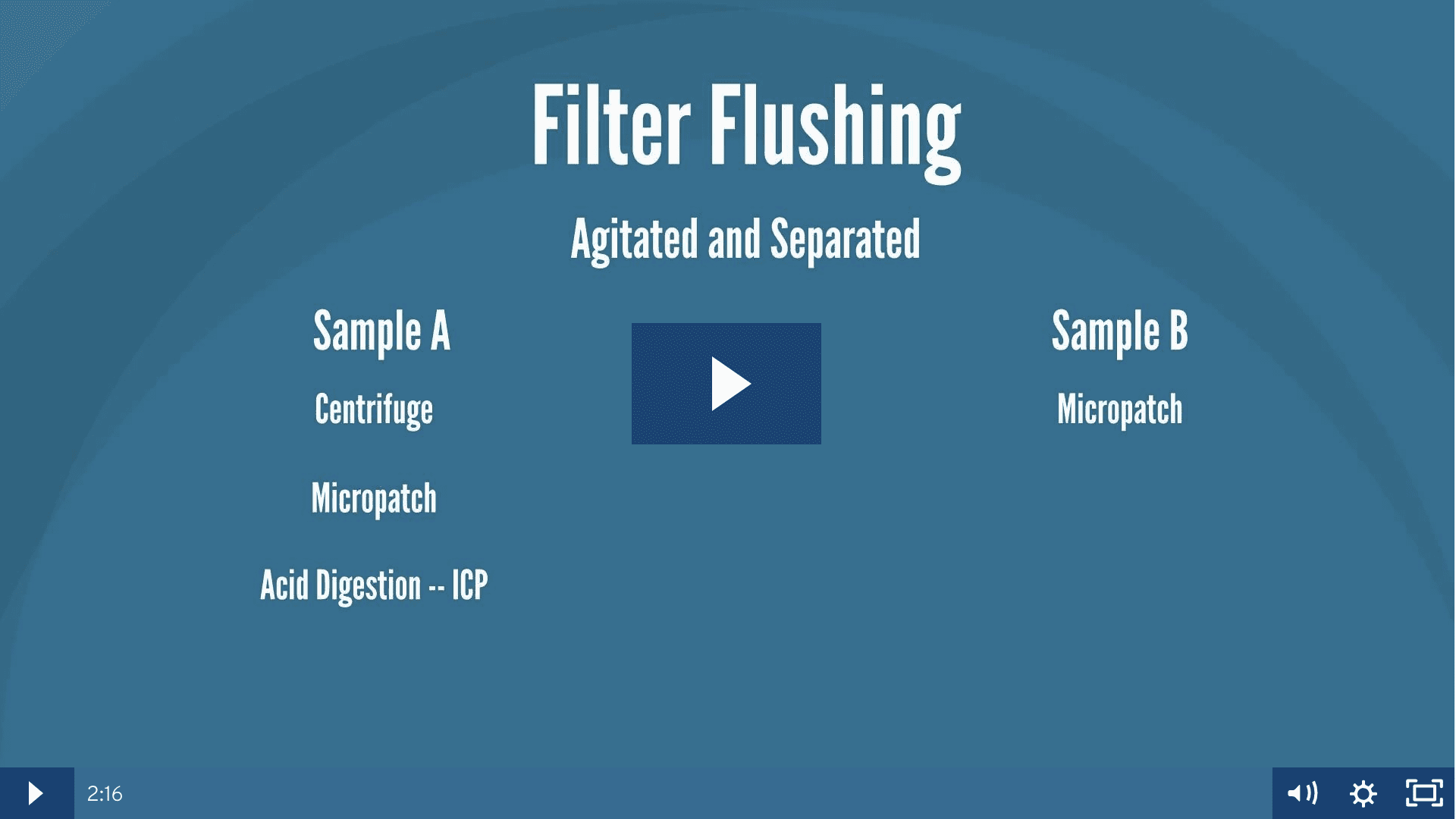

The FDA process involves flushing the filter, extracting the particles and performing several tests (including micropatch and analytical ferrography) to identify wear particles. Check out the video below to see how we perform Filter Debris Analysis at POLARIS Laboratories®:

Learn more about Filter Debris Analysis by reading our technical bulletin.

Interested in adding FDA to your current fluid analysis program? Contact customer service or your account manager.

Proven Impact. Proven Uptime. Proven Savings.

Let us prove it to you.