Why Too Much Coolant Corrosion Inhibitor Can Be Harmful

What are coolant corrosion inhibitors?

Coolant corrosion inhibitors help decrease the corrosion rate of metals within your equipment and help maintain other coolant properties. The coolant manufacturers will determine the type of coolant corrosion inhibitors utilized in their product. The main types of inhibitors are:

- Inorganic based (IAT)

- Organic based (OAT)

- Azoles

What coolant should I use?

The coolant you use while maintaining your equipment should utilize the same type of inhibitors as the coolant formulation that’s already in your system.

Here are some ways to make sure your fluid is able to properly protect your equipment:

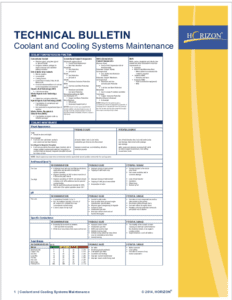

- Testing with test strips (see technical bulletin below)

- Using fluid analysis laboratories

- Following recommendations on how to maintain inhibitor for the specified fluid type

We know low corrosion inhibitors for heavy duty applications leave our equipment vulnerable to corrosion but, why is too much a problem?

Even though heavy duty equipment will require a higher level of inhibitors compared to light duty equipment, a specific range must be maintained for proper protection. Adding too much coolant corrosion inhibitor to the cooling system, no matter what type of inhibitors are utilized in the fluid, will impact other coolant properties. The pH and specific conductance will increase which will lead to corrosion concerns.

Another concern is the coolant’s saturation point. When the saturation point (where no more inhibitor can be absorbed in the coolant) is reached, the inhibitors will drop out and a precipitate will form. The precipitation will cause plugging of the coolant passage ways.

When this occurs the coolant will no longer be able to prevent corrosion of the metals that come in contact with the coolant.

When this occurs the coolant will no longer be able to prevent corrosion of the metals that come in contact with the coolant.

What a coolant corrosion inhibitor drop out means

A major function of the cooling system will be impacted due to the drop out of coolant corrosion inhibitors. This important function is coolant flow. When the coolant cannot effectively circulate through the engine due to precipitation restricting coolant flow we lose our capability for heat transfer. Without proper heat transfer we will experience engine overheating and may cause further engine damage. Both scenarios of too little or too much coolant corrosion inhibitor will negatively impact your equipment and overall decrease your equipment’s reliability. Maintaining the correct coolant corrosion inhibitors in the recommended ranges per coolant manufacturer recommendations will provide the best protection for your equipment.

Below are some technical bulletins with additional information on coolants, coolant test strips and high performance liquid chromatography (HPLC).

Proven Impact. Proven Uptime. Proven Savings.

Let us prove it to you.