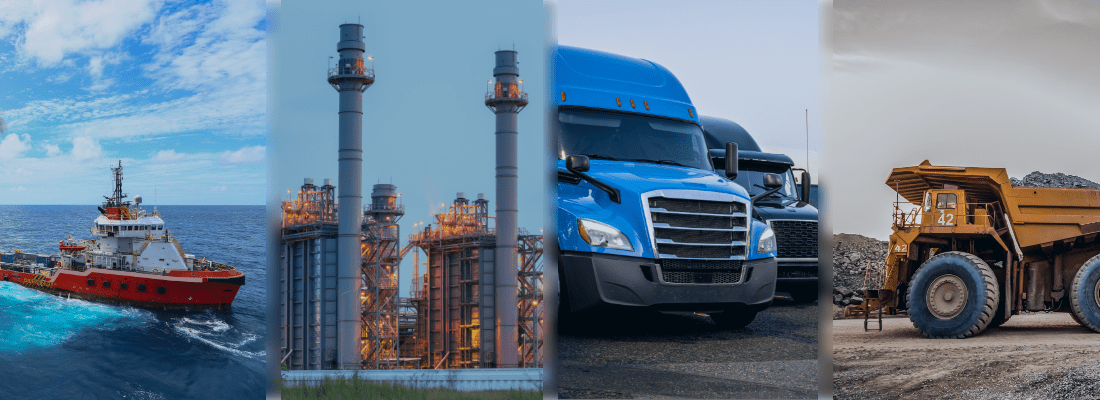

Addressing Industry-Specific Coolant Concerns with Analysis

Maintaining your cooling system does not have to be a complicated task or result in a neglected system. Understanding the fluid and equipment needs are key to proper maintenance in the field. With proper maintenance, the fluid and equipment health can provide the adequate functions to protect and remove heat from the component parts as needed.

Different applications and environments play a critical role and can exacerbate potential problems that may hinder the cooling systems ability to circulate, remove heat and then dissipate the heat before circulating again through the system. These functions are critical for the cooling system to maintain and protect the equipment. Adequate coolant testing based on industry can identify possible issues and/or concerns. Because the fluid chemistry plays a critical role in the cooling system’s ability to transfer heat and prevent corrosion which protects overall system health.

Off-Highway/Construction

In today’s market, there is a high demand to maintain equipment. The average life for most fleets is 3.5 to 4 years, however, due to supply issues and current economic conditions, many are looking to extend the life of their fleet. Common coolant system concerns that can result in issues are often overlooked until failure occurs. These concerns can be monitored as part of an effective predictive maintenance program:

- High Temperature Issues

- Glycol concentration

- Chemistry Issues

- Corrosion inhibitor

- Mixing

- Contamination

- Scale hardness

- Glycol degradation

Manufacturing

Higher ambient temperatures in different equipment types may require different fluids to maintain system temperatures. Monitoring and knowing the fluid types are key for proper maintenance. Common coolant system concerns to monitor include:

- OEM Requirements and Coolant Supplier Support

- Understanding equipment recommendation for glycol to water concentrations

- Contamination Issues

- Scale hardness

- Glycol degradation

Power Generation

The duty cycle for this industry is “long term, low maintenance” requiring a focus on the coolant chemistry. Typically, fluids in the system are in a state of inactivity. Operating only when needed, when serviced or when demand is required. Common coolant concerns to monitor are:

- Contamination

- Degradation acids

- Grounding concerns

- Air leak

- Scale

- High temperature

- Glycol concentration

- Maintain proper OEM glycol to water concentration

- Chemistry issues:

- Corrosion inhibitor

- Mixing

- Glycol concentration

Marine

The marine industry encompasses a large range of coolant systems; however, these systems will be deployed with very little access to repair parts or facilities for extended times. Increasing the system’s integrity is critical. There is a wide variety of coolant formulations to meet proper regulations and knowing the coolant formulation is key for making adjustments when needed.

- Chemistry issues

- Mixing

- Maintaining proper fluid corrosion inhibitor levels

- Understanding equipment recommendation for glycol to water concentrations

- Contamination issues

- Air leaks

- Internal/External contamination concerns

Transportation

With concerns of raising inflation, high fuel prices and changes in supply availability demands, keeping equipment in operation and extending all fluid life are becoming more of a necessity. Common coolant system concerns (often overlooked until related failure occurs) can be monitored as part of an effective predictive maintenance program.

- High Temperature Issues

- Glycol concentration

- Freeze point and boil point protection

- Chemistry issues

- Corrosion inhibitor

- Mixing

- Contamination

- Scale hardness

- Glycol degradation

- Glycol concentration

Learn more about test methods for coolants here.

Overall, all industries will have similar goals to maintain equipment and get the full life from the equipment as expected, if not longer. With proper fluid analysis and monitoring, concerns can be identified early before further damage internal causes a premature failure.

If you’re interested in learning more about recommended coolant testing and analysis for different industries, sign up for our upcoming webinar What Coolant Testing is Right for You? on August 25, 2022 at 11 a.m. ET.

Reach out to our team to see how we can support your fluid analysis program and help increase uptime in your fleet.

Proven Impact. Proven Uptime. Proven Savings.

Let us prove it to you.