Assessing Methods to Analyze Particles: PQ vs FerroQ

What is Ferrous Debris?

The metallic fragments that linger onto lubrication oil are referred to as Ferrous Debris and have always posed an obstacle for condition monitoring laboratories or end-user facilities. Historically, there has always been challenges with spectroscopic methods not fully analyzing the ferrous debris load lower than about 10µm in diameter.

Credit to the Swansea Tribology Centre, the PQ has globally been an essential component of oil condition monitoring programs since 1985 to combat the full analyzation limitations. The PQ is a sensitive magnetometer that measures the influence on a magnetic field and provides a quantitative result of the ferrous wear in a sample. This result can be trended with acceptable linearity over a wide range of ferrous debris concentrations and particle sizes.

Limitations and Solutions of PQ

PQ comes with certain limitations that can disrupt the process of receiving accurate measurements for Ferrous Debris amounts. These limitations include bottle measurements only analyzing around the bottom centimeter or standards not being available from the manufacturer, thus not NIST traceable. Additionally, there is the issue that the result are unitless due to the PQ Index referring to a dimensionless number.

Fortunately, newer instruments such as Poseidon FerroQ was developed to meet these limitations which uniquely uses a set of coil windings; one for measurement and one for reference. When the sample is inserted, any ferrous material present in the oil/grease sample changes the inductance of the measurement coil relative to the reference coil. A sensitive signal conditioning circuit detects those minute changes in inductance of the measurement coil and the embedded processor interprets this signal to provide a mass/volume output based on calibration standards.

Single coil products such as PQ and certain PPM devices typically yield different results than set coil products such as FerroQ. This results in a device that is highly sensitive to particles at the bottom of a sample and insensitive to those at the top. FerroQ measurement coil surrounds the sample, providing uniform sensitivity, and superior repeatability.

How FerroQ is Measured?

The FerroQ reports results in mg/kg and utilizes standards that are NIST traceable back to a primary iron standard. This gives a result that is quantifiable and meets quality standards more fully.

To confirm the traceability and accuracy of the results from the FerroQ, 0.0151g of Iron Powder, <10 µm, ≥99.9% trace metal basis from Sigma Aldrich was prepared in 10.0007 g total of a UV reactive resin. The theoretical result was 1510 mg/kg.

| Tube | Replicate 1 | Replicate 2 |

| #1 | 1620 mg/kg | 1630 mg/kg |

| #2 | 1610 mg/kg | 1640 mg/kg |

| #3 | 1590 mg/kg | 1590 mg/kg |

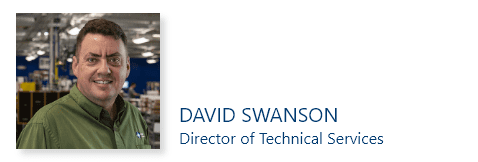

There is a desire in some laboratories to switch from the venerable PQ to the FerroQ. To determine this, 1291 comparisons were made.

Using all data did show that above 1000 PQ™ Index the data did have a skew. This is likely the effect of PQ™ does nor analyze the whole sample.

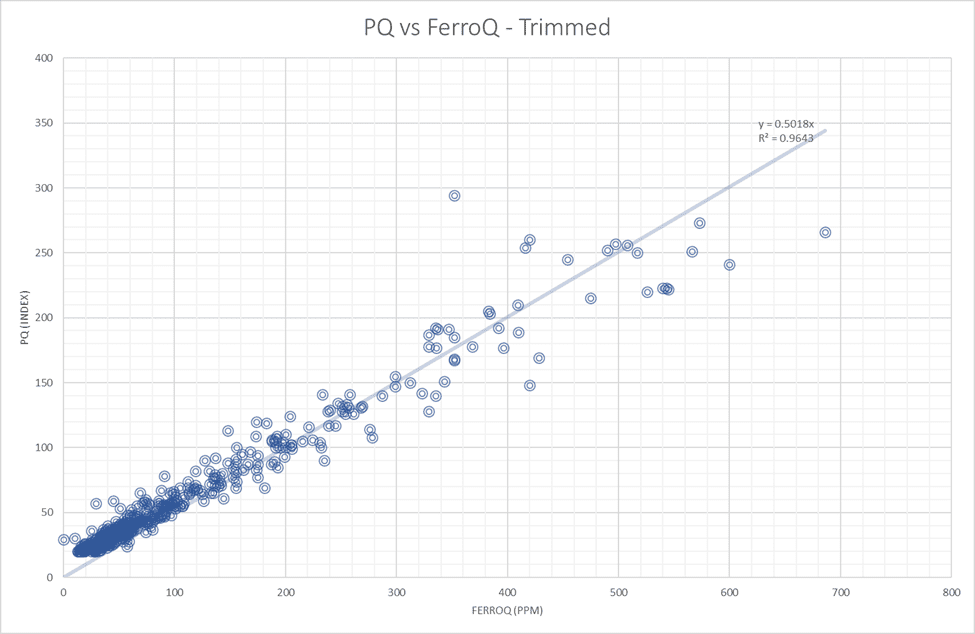

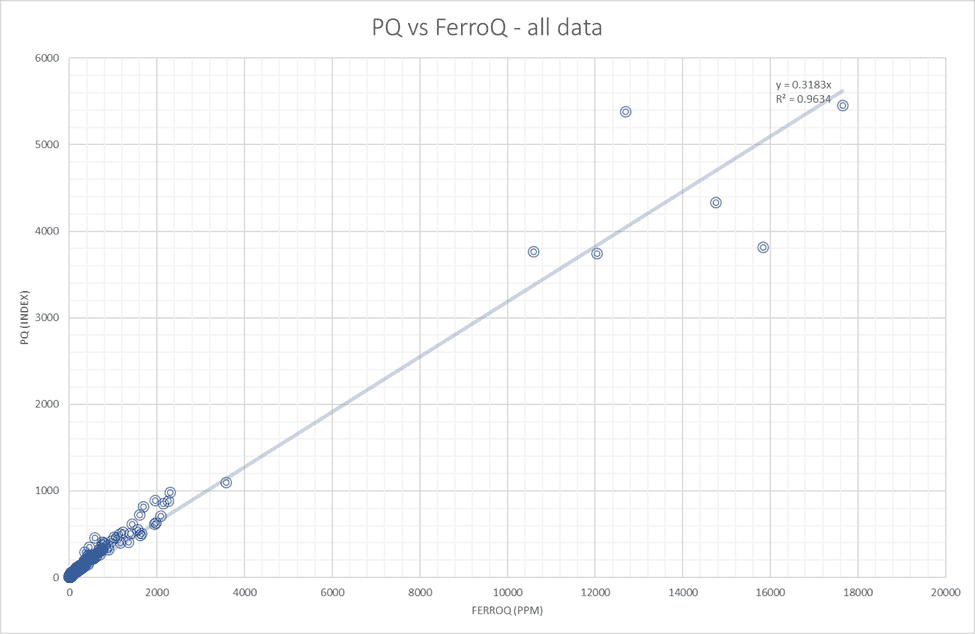

Removing this data shows a definite correlation between the two methods:

In summary, the FerroQ technology shows that it will perform similarly to the PQ technology. This coupled with the FerroQ having NIST traceable standards, reporting in mg/kg, and analyzing the entire sample (as opposed to only the bottom) that it may be a superior method to the venerable PQ.

Proven Impact. Proven Uptime. Proven Savings.

Let us prove it to you.

Published March 21, 2024