Coolant Condition Monitoring: Comparing Testing

Include Cooling Systems in Regular Maintenance

Coolant testing is an important aspect of maintaining the cooling system. Part of your normal maintenance schedule should include inspecting the cooling system at every maintenance interval. During operation, the cooling system must 1) circulate coolant, 2) transfer heat away from the engine and 3) dissipate the heat through the radiator to the atmosphere before circulating back through the engine again. These three functions must occur efficiently to maintain the proper operating temperature. If the lubricant is showing increased wear, increase in viscosity and or oxidation, the cooling system should be tested. Cooling system health effects how well the equipment will operate and ensures the ability for the fluids in the system to protect the equipment metals from damage.

To verify the coolant properties are adequate, testing becomes a critical part of system maintenance. Field testing conducted on-site should be a used as a screening tool to determine if laboratory testing is required earlier than scheduled. Laboratory testing is a critical part of any fluid analysis program in addition to field testing.

Field Testing & Laboratory Testing

Field testing includes monitoring visual characteristics of the coolant using test strips to determine corrosion protection levels, pH and or freeze point. A handheld refractometer for testing glycol percent is another useful tool. Some limitations with field testing include: coolant with a normal appearance could be misleading, low precision and limited scope of testing. Most laboratory testing will report results in parts per million and detect various materials smaller than the eye can see. Laboratory testing can be used to determine the validity of concerns with corrosion of system metals, hard water contamination, early degradation breakdown of the glycol and other chemical properties. Laboratory testing is typically recommended to be conducted twice a year for normal use engines (Spring & Fall) and every quarter for high-hour or extreme duty engines.

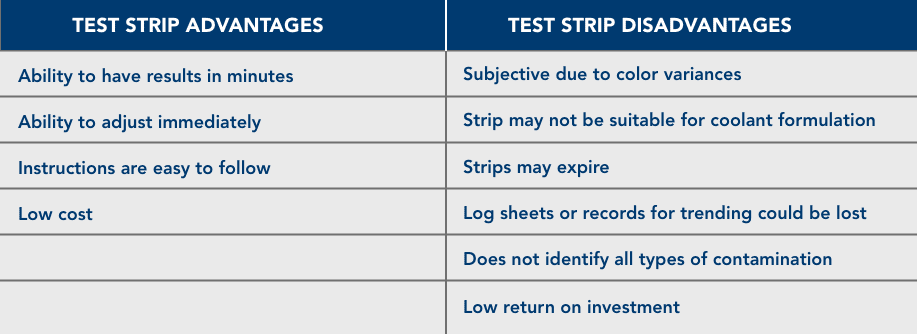

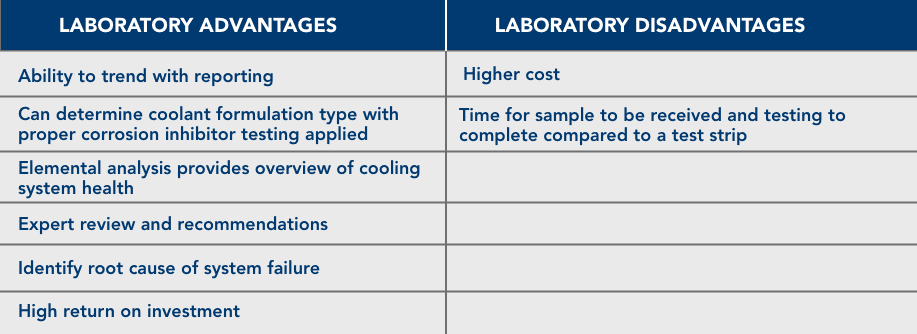

There’s more to coolant analysis than testing coolant formulations – it’s about identifying problems within the cooling system that can be detrimental to engine performance and lead to premature engine failure. Below are some advantages and disadvantages of using coolant test strips and laboratory testing.

Proven Impact. Proven Uptime. Proven Savings.

Let us prove it to you.

Published February 9, 2023