Throwback to 1988

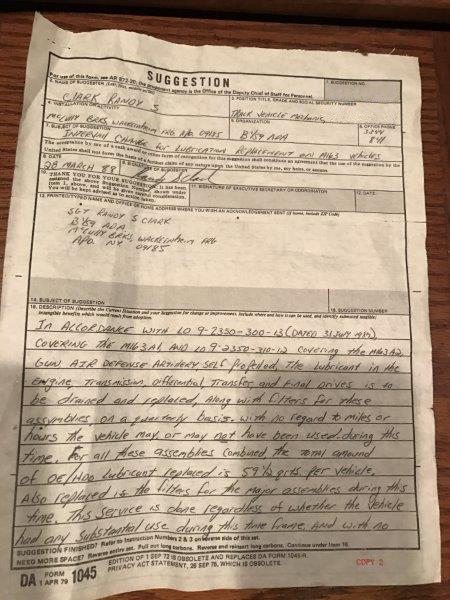

Flashback to 1988 when “Rain Man” first appeared on the silver screen and Ronald Reagan was serving his last full year as president. I was serving in the U.S. Army and stationed in Germany in an air defense unit. At that time, I held the rank of sergeant with a military occupation specialty (MOS) of 63Y20, Track Vehicle Mechanic.

The two images below are forms DA 1045, the official form used if you wanted to suggest any changes to the Department of the Army. I filled out and submitted these forms in March of 1988 with a suggestion that the army change their maintenance practice on M163A1 and M163A2 Vulcan Air Defense Guns.

The M163 series included 20mm Gatling Cannons mounted on the very popular M113 series armored personnel carriers. The maintenance practice at the time was to replace the oil and filters in the engine, transmission and all gear boxes on a 90 day interval, without consideration for hours on the oil. This time based interval of 90 days seemed to be a potential waste of lubricants, filters, labor and the added burden of waste disposal.

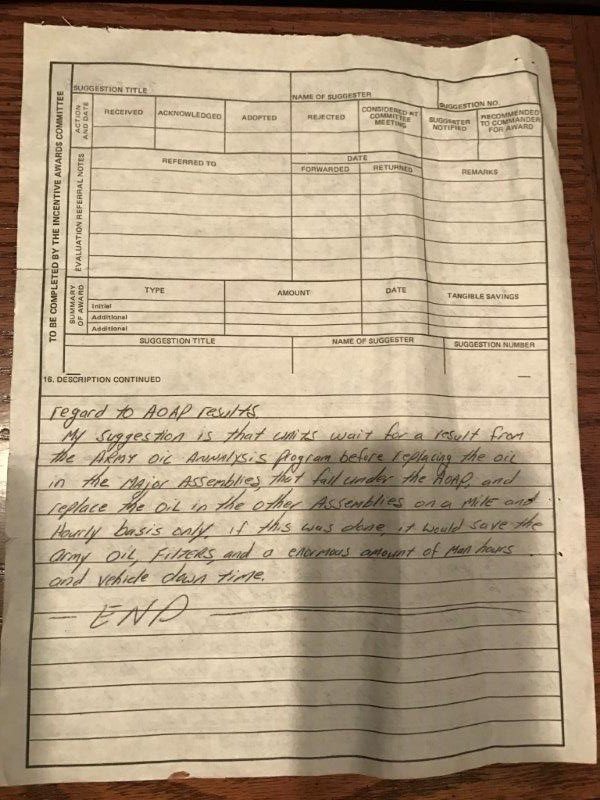

My suggestion was simple, rely on oil analysis results to determine the proper oil drain interval. We were already using the Army Oil Analysis Program (AOAP) to monitor the condition of components, why not use it to monitor the condition of the oil?

Since I submitted those reports, the industry has proceeded to evolve and, for many, using oil analysis to optimize drain intervals is now a common practice. Advances in technology have made handwritten reports, such as these, a thing of the past. I can only imagine how much easier my job would have been had I access to all of the tools available today.

If you’re interested in learning more about my experiences or how to optimize drain intervals by using oil analysis, feel free to email me at rclark@polarislabs.com or connect with me on LinkedIn.

Proven Impact. Proven Uptime. Proven Savings.

Let us prove it to you.