Detect Equipment Wear Sooner with Ferrous Debris Analysis

In the world of heavy-duty equipment, small issues can quickly become big problems. A worn bearing or damaged gear doesn’t just cause mechanical headaches , it can lead to costly downtime, safety risks, and unexpected repairs. That’s why early detection of wear is one of the most valuable tools in any maintenance strategy.

One of the most effective ways to spot wear early is through ferrous debris analysis. This is a key part of fluid testing that helps you understand what’s happening inside your equipment long before performance declines.

What is Ferrous Debris?

Ferrous debris refers to the tiny metal particles (typically iron and steel) that are generated when internal components begin to wear. These particles are carried in the lubricant and can tell a detailed story about what’s happening inside an engine, gearbox, or hydraulic system.

While some wear is normal, a sharp increase in ferrous debris is often one of the first signs that something is going wrong. Identifying these particles early helps maintenance teams take corrective action before the wear turns into failure.

Why Testing Matters

Routine oil analysis provides an overview of fluid health and contamination, but ferrous debris testing focuses specifically on wear; the earliest and most direct indicator of mechanical distress. By trending ferrous data over time, maintenance professionals can spot abnormal wear patterns and schedule repairs before they become emergencies.

The Next Generation of Wear Detection: FerroQ

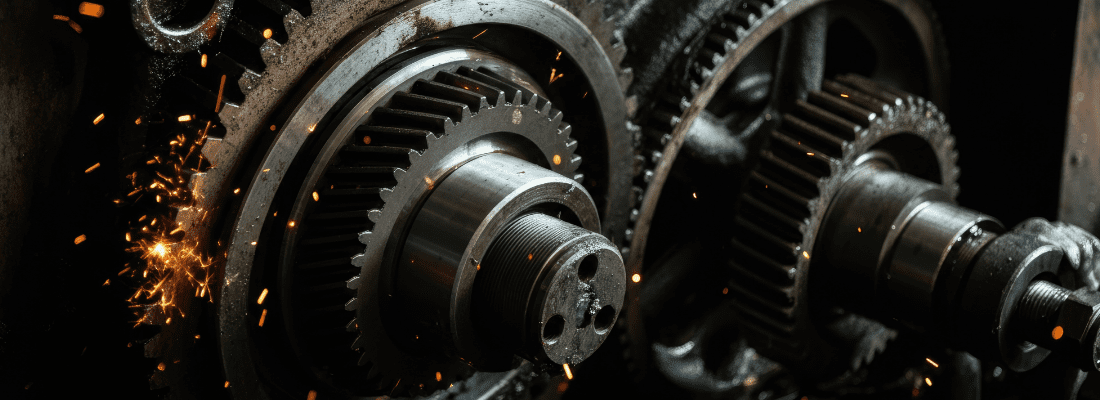

Traditionally, laboratories have used Particle Quantifier (PQ) testing to measure the amount of ferrous material in a lubricant sample. While effective, PQ testing can have limitations when dealing with complex samples or heavy contamination.

That’s why POLARIS Laboratories® has implemented the FerroQ method across all laboratory locations. FerroQ is an advanced approach to ferrous debris analysis that delivers more accurate, consistent, and repeatable results — giving you a clearer picture of equipment condition. Learn more about the switch here.

With FerroQ, you get:

-

Improved precision for detecting even small changes in wear levels

-

Faster, more reliable trending for better long-term insight

-

Consistent results across all POLARIS Laboratories® locations

This consistency ensures that wherever you send your samples, you’ll receive the same high-quality data, making it easier to monitor trends and take action with confidence.

Turning Insight into Action

Ferrous debris analysis doesn’t just measure metal content — it helps identify the type of wear occurring. When combined with techniques like Analytical Ferrography, maintenance teams can determine whether particles are from normal rubbing, cutting wear, or fatigue failure.

This level of insight allows you to move from reactive maintenance to a truly proactive, data-driven approach — extending equipment life, improving reliability, and maximizing return on investment.

The Bottom Line

When every hour of uptime matters, early detection makes all the difference. With advanced ferrous debris testing like FerroQ, you can identify wear before it becomes damage — keeping your equipment running stronger, longer.

Published October 24, 2025