2024 Reliability Summit: Europe

All Aboard for Reliability Training

POLARIS Laboratories® is heading to Europe for this year’s Reliability Summit for two days of reliability training lead by our industry’s seasoned veterans. Speakers will cover topics such as developing maintenance strategies, fluid analysis data management, technical with testing and more. In addition, this year’s summit gives you a chance to appreciate a gorgeous waterside view during sessions or in your free time.

Reliability Summit: When and Where?

The countdown to register for the 2024 EU Reliability Summit has begun as the conference will take place May 14, 2024 to May 15, 2024. Attendees will be headed to Rotterdam, Netherlands to enjoy May by the bay within one of the largest and most beautiful cities in the Netherlands. The venue, aboard the SS Rotterdam, invites attendees to enjoy a variety of speakers, accommodations and more.

Visit event site for more info and to register

Reliability Summit Speakers and Agenda:

We’ve brought in several reliability experts from both Technical and HORIZON® to host a range of seminars for our guests to attend. Speakers include:

Program Improvements

- Hermen Kamp, Asset Manager – Global Projects & Assets, Mammoet

- Reliability Revolution: Transforming Operations Through Continuous Improvement

- May 14, 1:10 p.m. CET

- Reliability Revolution: Transforming Operations Through Continuous Improvement

- Gwyn Simmonds, Executive Director Global Sales & Marketing, POLARIS Laboratories®

- HORIZON: Your Gateway to Optimized Data Management

- May 15, 10:35 a.m. CET

- HORIZON: Your Gateway to Optimized Data Management

Technical with Testing

- Mark Barnes – Senior Vice President, Global Business Development, Des-Case Corporation® by Timken

- Lowering Carbon Footprint Through Aggressive Contamination Control

- May 14, 3:20 p.m. CET

- Lowering Carbon Footprint Through Aggressive Contamination Control

- Gijs van Schaik – Sales Director, EMEA RMF Systems, BV, Des-Case Corporation® by Timken

- Lowering Carbon Footprint Through Aggressive Contamination Control

- May 14, 3:20 p.m. CET

- Lowering Carbon Footprint Through Aggressive Contamination Control

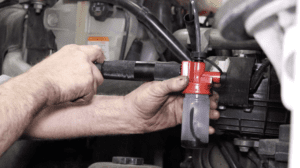

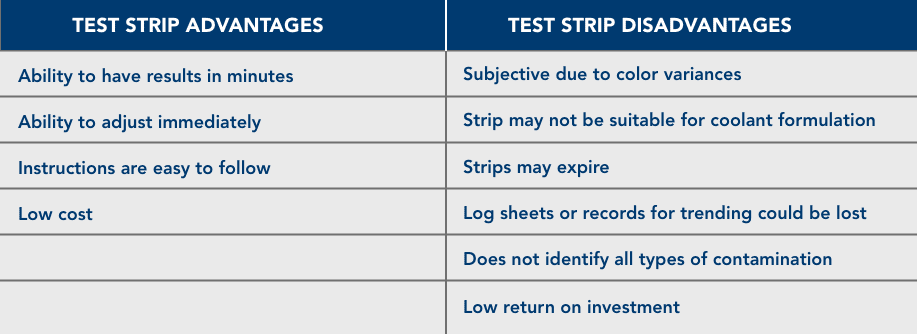

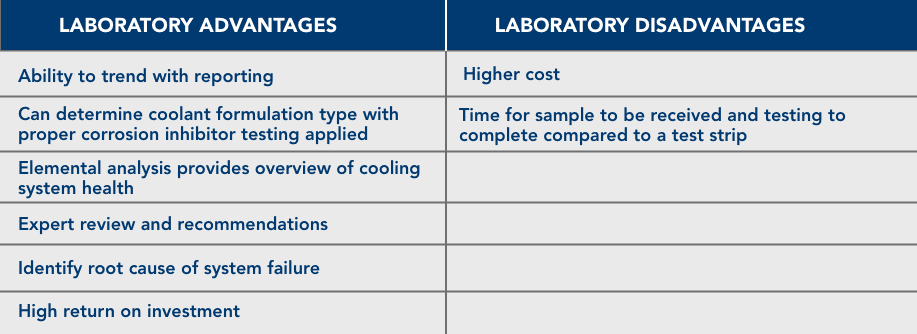

- Emily Featherston – Product Application Supervisor, POLARIS Laboratories®

- Demystifying Coolants: Selection, Application and Maintenance

- May 14, 04:15 p.m. CET

- Demystifying Coolants: Selection, Application and Maintenance

- Paul Withing – Chief Executive Officer, DeltaXero

- From Monitoring to Mitigation: Combatting Varnish

- May 15, 09:20 a.m. CET

- From Monitoring to Mitigation: Combatting Varnish

Reliability Summit: What’s New?

New Sails; New Sights

This year’s summit is all about learning in a stunning environment. The SS Rotterdam is majestic boat spanning 228 meters long, 28 meters wide, and 51 meters high. This historical flagship offers an impressive sight of the city and waters that coincides with POLARIS Laboratories’ vision of discovery and adventure.

Training Within the Crystal Blue City

Rotterdam, Netherlands is a magnificent city filled to the brim with culture, history and charm. Its elegance offers a unique backdrop for attending this industry professional development and maintenance conference.

Published April 11, 2024