Case Study: Connecting Fluid Analysis with Equipment Maintenance

Today’s oil analysis capabilities offer a great deal more than just monitoring component health. With today’s technology, along with performing the proper tests, we can:

Why Testing Now is Crucial

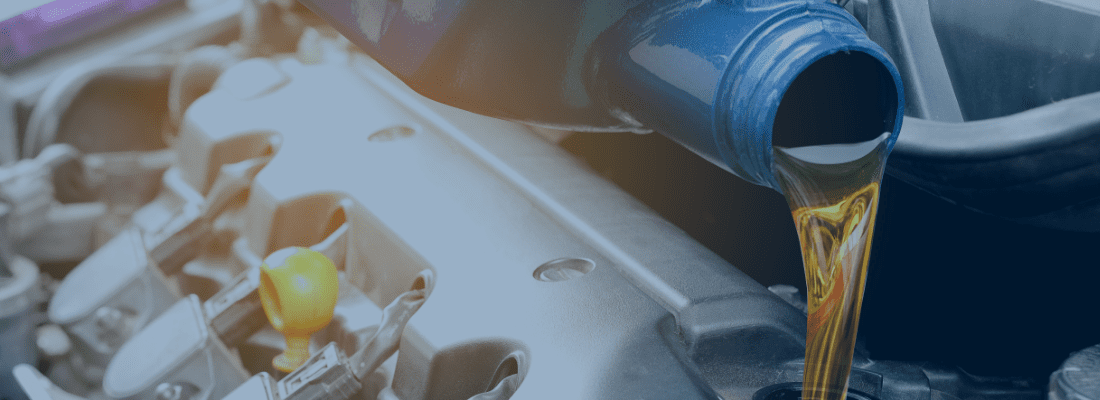

In today’s world, there’s another reason for oil analysis and why you need to do it now more than ever. Over the past many months, lubricants have been and continue to be in short supply. This is being caused by increased demand, additive shortages, logistics delays and a shortage of delivery drivers. Unfortunately, many companies are on allocation and only receiving partial amounts of their lubricant delivery. If you can’t get the lubricant supply you need, it might be a good time to look at how to get more out of the lubricant you already have.

Condition-Based Monitoring

Oil analysis is the tool to extending and optimizing drain intervals without compromising your equipment reliability. Many customers are still doing a preventive maintenance (PM) program, rather than a condition-based monitoring program. Often times, when a used oil sample is sent to the laboratory, the oil has already been disposed of. Now is the ideal time to look at moving to a condition-based monitoring program and let the laboratory’s data guide you on how much farther you can safely go with the lubricant you have in service. Ultimately, optimizing drain intervals reduces cost and waste, and helps lower maintenance costs when done correctly.

So, with finished lubricants in short supply right now, plus the ever increasing price of crude oil in today’s world (which ultimately raises the price of finished lubricants) one of your best options might be to consider extending your oil drains with “extended drain comments” from the data analysts and subject matter experts at POLARIS Laboratories®. Please see below an example of a used oil analysis report with “extended drain comments”:

Proven Impact. Proven Uptime. Proven Savings.

Let us prove it to you.

POLARIS Laboratories® helps improve your equipment reliability through a full suite of fluid testing, certified analysis and data integration to get your maintenance on the right track.

OUR SITE

SERVICES

Oils/Lubricants

Coolants/Antifreeze

Diesel Fuel

Grease Analysis