By utilizing our experts’ knowledge, experience and recommendations, we regularly publish educational and insightful blogs. These blogs serve as resources to help you expand your learnings, explore new testing capabilities, find ways to improve your fluid analysis program and discover data integration solutions to help you increase your reliability.

https://polarislabs.com/wp-content/uploads/2024/03/PQ-Ferro-Q-featured.png

400

800

POLARIS Laboratories

https://polarislabs.com/wp-content/uploads/2021/06/POLARIS-Logo-Blue-Gray@2x.png

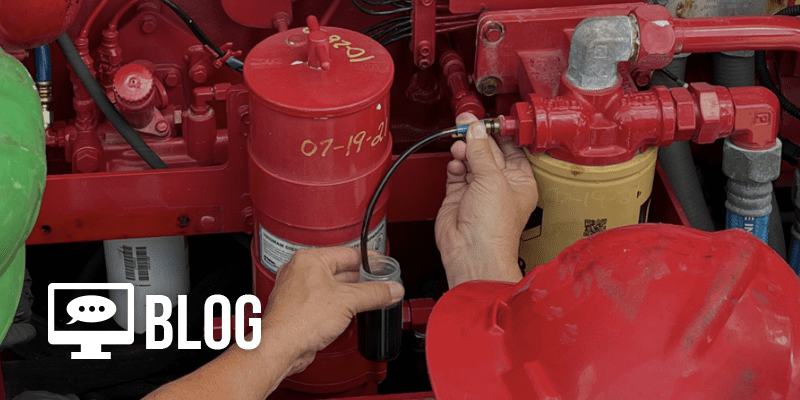

POLARIS Laboratories2024-03-21 11:23:552024-03-21 11:25:11Assessing Methods to Analyze Particles: PQ vs FerroQ

https://polarislabs.com/wp-content/uploads/2024/03/PQ-Ferro-Q-featured.png

400

800

POLARIS Laboratories

https://polarislabs.com/wp-content/uploads/2021/06/POLARIS-Logo-Blue-Gray@2x.png

POLARIS Laboratories2024-03-21 11:23:552024-03-21 11:25:11Assessing Methods to Analyze Particles: PQ vs FerroQ