4 Tips for Shipping Success

Whether you’re submitting oil, coolant or diesel fuel samples for testing, mailing the samples can be tricky, especially if the sample jar lid is not tightened securely onto the sample jar. Loose lids can cause leakage and delay the processing of your sample. Here are some helpful tips to not only ensure your samples arrive at our laboratories in a timely manner, but improve your testing experience too.

1. Secure Sample Jars

Make sure the sample jar lids are closed tightly. Fluid pulled from equipment will likely be hot, and this may cause the lid to loosen after the fluid cools down. Also, too much fluid in the neck of the bottle will also cause the lid to loosen as well. Be sure to only fill the sample bottle to the designated Fill Line and make sure the jar is closed tightly by re-tightening the lid by hand until snug. You may also use a strip of silicone tape to secure the lid, but it is not required.

2. Shipping Container

If a hard or soft plastic mailer was provided with the sample jar, place the sample jar inside it and close it securely. The sample can be shipped in that container or protected further by placing it inside a box. Insert packing material to make sure the samples do not shift during the shipping process.

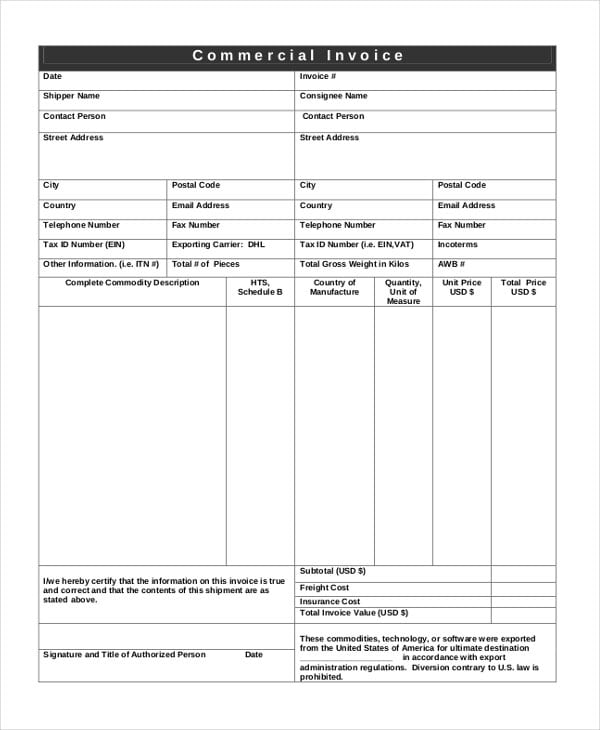

3. Commercial Invoice

International shipments to the United States require a commercial invoice to categorize the items being shipped. Oil and coolant samples should be categorized as Non-hazardous lubrication oil/coolant samples. Tested to destruction. Not Restricted by I.A.T.A. No commercial value. Flash Point >200°C. It is recommended to declare the value of the entire shipment as $10.00. Below is a sample of a commercial invoice.

4. Shipment Services

Listed below are some of the more common shipping carriers that deliver packages to our testing laboratories. In order to receive your results back in a timely manner, we recommend using services that can track the location of your package so you are able to track down your sample if shipping errors occur.

- Canada: Canada Post, Loomis, FedEx, UPS and independent couriers

- Guatemala: DHL, FedEx, Guatemalan Post, UPS and independent couriers

- Poland: DHL, FedEx, Polish Post, UPS, and independent couriers

- United States: DHL, FedEx, UPS, United States Postal Service (USPS) and independent couriers

Proven Impact. Proven Uptime. Proven Savings.

Let us prove it to you.