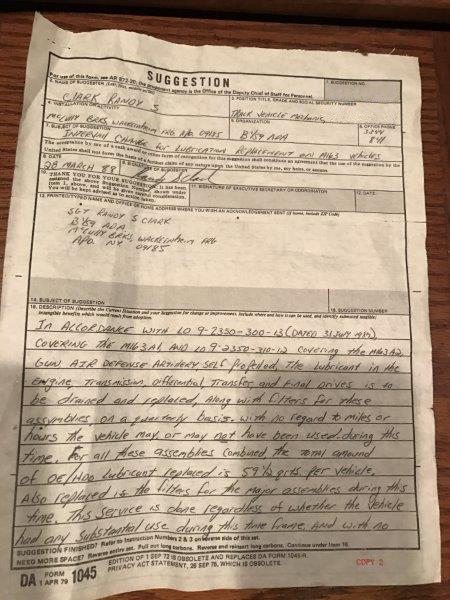

Read this Q&A to learn how our technical business consultants, Randy Clark and Henry Neicamp, can help you improve your maintenance program.

What is a technical business consultant?

Randy: I once had someone tell me that a consultant is someone who ‘borrows your watch and then tells you what time it is’. In some ways, this is true. We take an in-depth look at our customers’ fluid analysis statistical data and use this information to assist them in narrowing the focus and priorities of their maintenance program, thus achieving their goals quickly and efficiently. These goals typically include reducing unplanned/unscheduled maintenance activities, reducing cost, and ultimately increasing production by improving equipment availability.

Henry: POLARIS Laboratories® technical business consultants are STLE certified to provide training and consulting services, along with data analysis services, in an effort to help the customer maximize the return on investment of their fluid analysis program and realize Proven Impact, Proven Uptime and Proven Savings!

How do you help our partners reach their reliability goals?

Randy: We accomplish this by first understanding the goals the customer wishes to achieve, we then perform a gap analysis to understand where the customer is today in relation to those goals, and then help develop a clear road map to the objective. We do this using our ‘hands on’ experience, knowledge of industry best practices, and in-depth knowledge of fluid analysis. We then combine our skills with the customer’s knowledge of their equipment. Along the way, we identify KPI’s (Key Performance Indicators) to monitor the progress. We also identify and share ‘quick wins’. Doing this accelerates the buy-in process among everyone involved and promotes the value of the program. Throughout the process, an emphasis on continuous improvement and training will play a key role.

Henry: The technical business consultants achieves this mission by providing consulting services, sales support, customer field support, and training for public and private sessions.

What is the most common problem you see in a newly created fluid analysis program?

Randy: Understanding the capabilities a quality fluid analysis program offers, and then aligning the goals of your program with those capabilities is essential. Many customers make a decision to start a fluid analysis program and yet do not ensure the test package selected is designed to meet those goals. Failing to properly identify, in advance, what equipment will be sampled, the frequency of the sampling interval, and the lack of proper training can be detrimental to the success of the program.

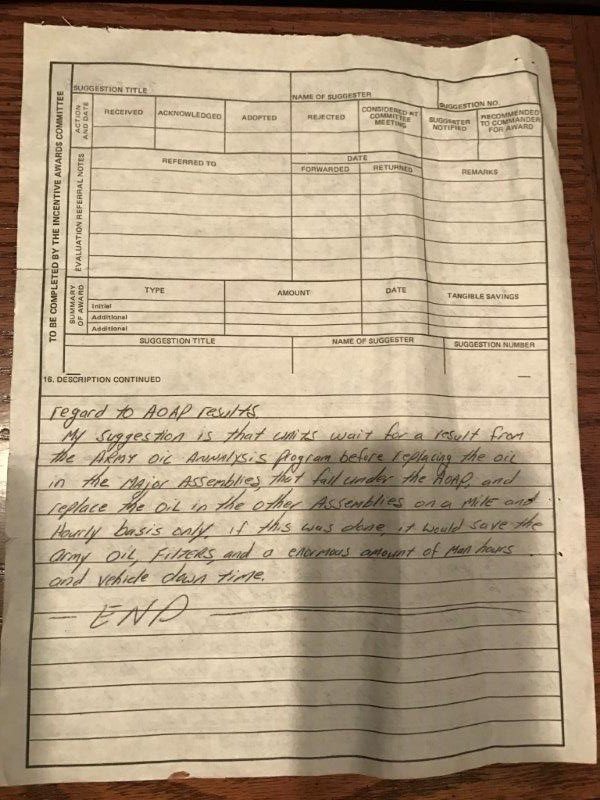

Henry: Customers do not take the time to determine the goals for their fluid analysis program (i.e. reduce downtime, extend oil drain intervals, reduce failures, extend equipment life expectancy, control maintenance and lubrication costs, etc). Secondly, customers do not submit a completed equipment list to POLARIS Laboratories® for input into our system prior to submitting their samples.

What is the best piece of advice you have for someone trying to improve their fluid analysis program?

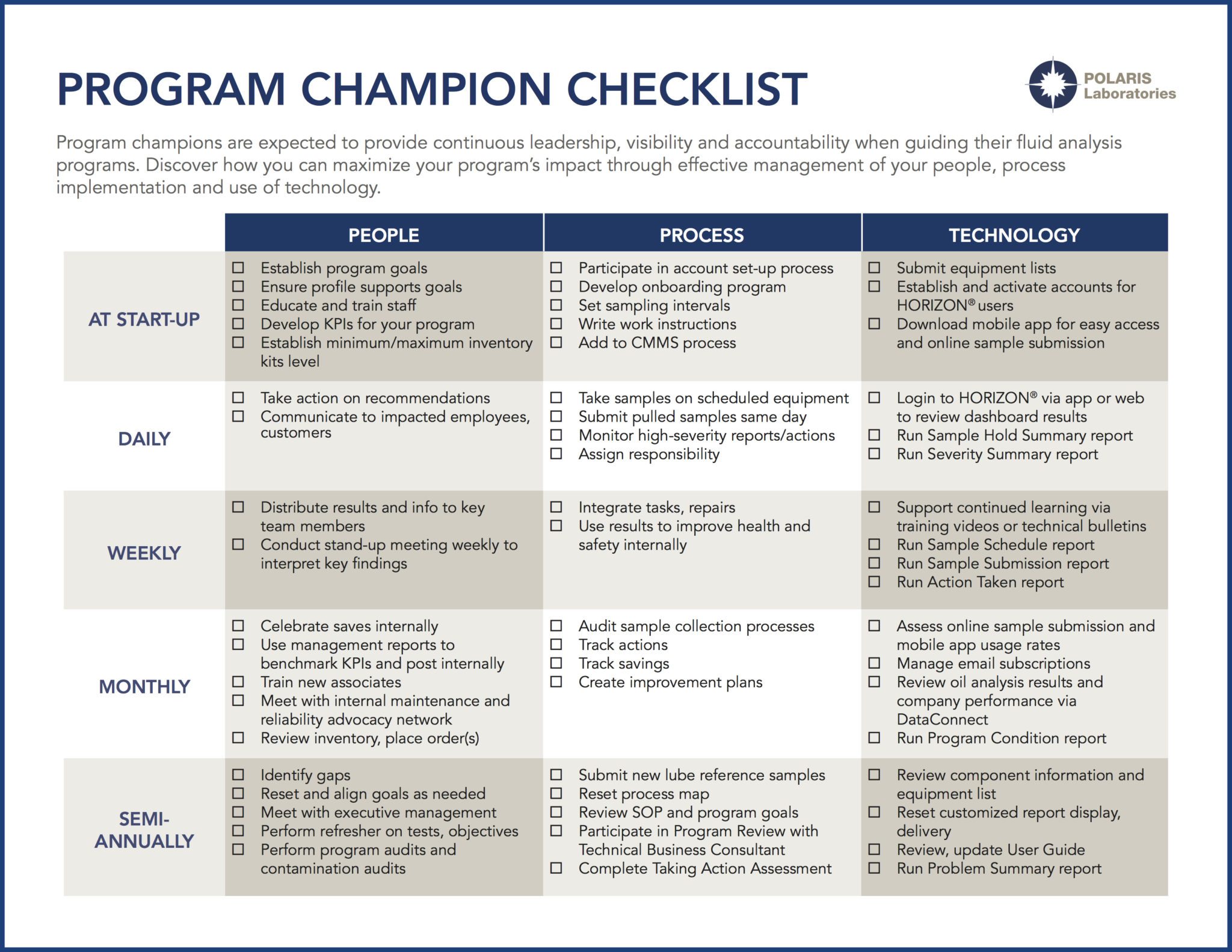

Randy: Establish goals, monitor progress and uphold accountability. This is best accomplished by having a program champion within the organization. This champion will ensure samples are pulled on time and pulled correctly. They will also ensure proper maintenance activity occurs following the laboratories’ recommendation. The champion will monitor progress and continuous improvement of the program, through established KPI’s, and will work with both their team members and the laboratory to optimize the value of the program.

Henry: The single most important ingredient in a successful oil analysis program is a “champion” inside it. A “champion” is a person assigned to take the lead and focus on the fluid analysis program. A “champion” should be passionate to save the company money, while working from the inside to generate greater customer implementation/compliance. A “champion” promotes the importance of fluid analysis to all maintenance personnel, and facilitates the required “behavioral change”.

What is the best way to set up a training class?

Randy: It doesn’t get any easier than this. Simply contact a POLARIS Laboratories® technical business consultant. We look forward to discussing and preparing a customized training plan to meet the needs and goals of your organization.

Henry: Customers should contact their respective technical business consultant (east or west) directly via email or phone.

Contact Randy Clark at rclark@polarislabs.com or via phone at 317.808.3750 x. 1337.

Contact Henry Neicamp at hneicamp@polarislabs.com or via phone at 317.808.3750 x. 1339.

To learn more about our technical business consultants’ services, download their brochure.

Proven Impact. Proven Uptime. Proven Savings.

Let us prove it to you.

![]() Set attainable program goals

Set attainable program goals![]() Identify the resources you need to sufficiently run the program

Identify the resources you need to sufficiently run the program![]() Build the appropriate equipment lists

Build the appropriate equipment lists![]() Determine sampling intervals

Determine sampling intervals![]() Take an active role in minimizing sample turnaround time

Take an active role in minimizing sample turnaround time![]() Report key results to management

Report key results to management![]() Select a laboratory that will help you every step of the way

Select a laboratory that will help you every step of the way