The HORIZON® Mobile App is Available for Android

Android users, we didn’t forget you! After unveiling the HORIZON® app for Apple in 2015, we have spent the last few months working diligently to develop the same easy-to-use app for Android devices. After all this hard work, I’m happy to announce the HORIZON app for Android is now available in the Google Play™ store!

The application, an extension of our award-winning fluid analysis software, is designed to make submitting your samples easy and reliable. No matter what device you’re using, a smartphone, tablet or computer, the HORIZON app and web versions are capable of syncing in real time, which means you can always rely on the app to keep you in the loop.

Whether you’re using Apple or Android, this app is designed to make your day easier. Using the mobile app allows you to stand right next to your equipment and enter fluid time, mileage and other information directly into HORIZON. This eliminates the need for paper submissions and the inevitable errors that come with it.

In addition, the app helps you manage your alerts, notifying you when your sample is complete and allowing you to adjust the alerts based on fluid

type and severity. The sample submission function also shows you the status of the sample (waiting, received, completed) in the sample submission list.

Don’t worry, if your phone battery is low, you can still access HORIZON on your web browser.

As we continue to identify ways to make your sample submission process easier, stay up-to-date on everything HORIZON through our monthly newsletter.

Download for Android

Download for Apple

Proven Impact. Proven Uptime. Proven Savings.

Let us prove it to you.

Android and Google Play are trademarks of Google Inc.

Our Data Analysis Team at POLARIS Laboratories® has

Our Data Analysis Team at POLARIS Laboratories® has

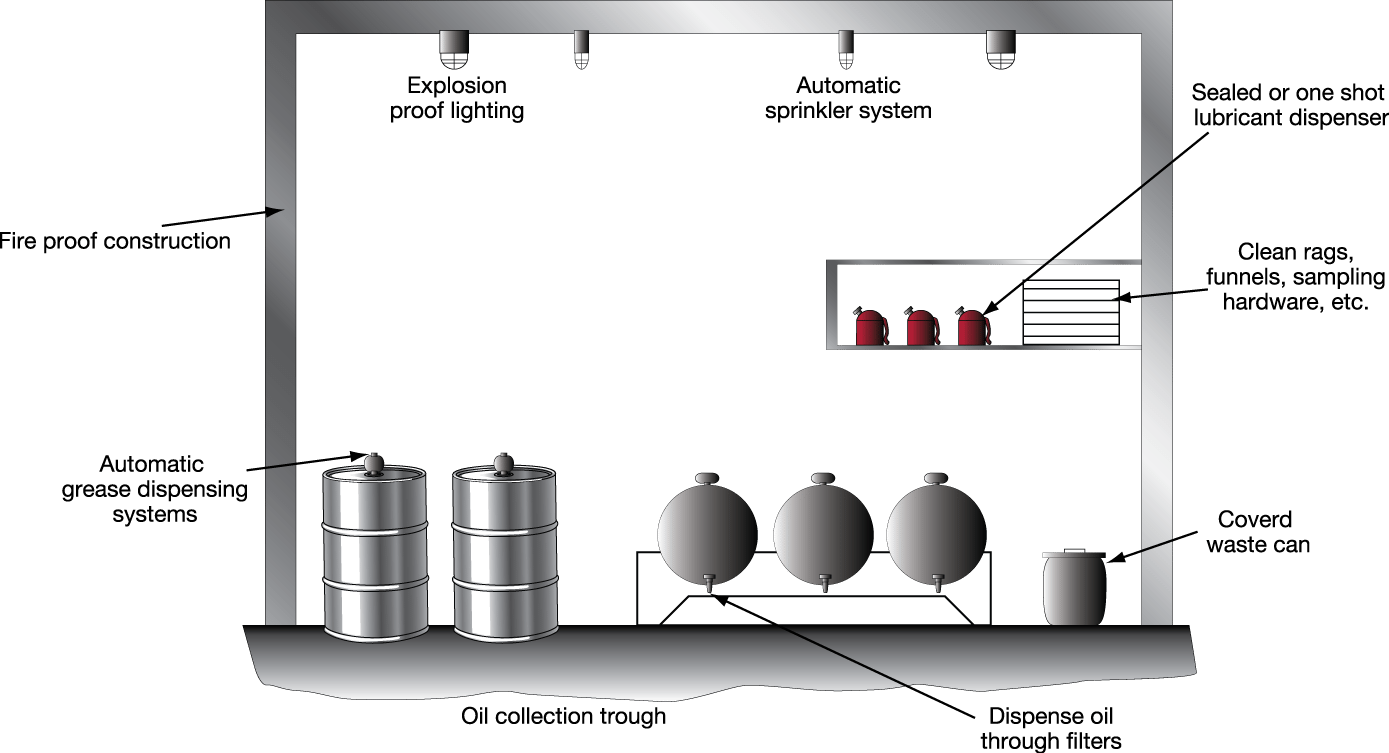

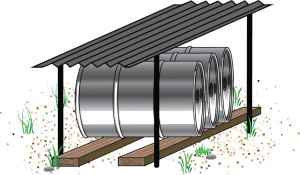

Engine manufacturers are realizing diesel fuel cleanliness can have great impact on overall engine performance. In fact, many are now recommending diesel fuel that does not meet an ISO Cleanliness Code of 18/16/13 should be filtered before introduction to the fuel system. Surprisingly

Engine manufacturers are realizing diesel fuel cleanliness can have great impact on overall engine performance. In fact, many are now recommending diesel fuel that does not meet an ISO Cleanliness Code of 18/16/13 should be filtered before introduction to the fuel system. Surprisingly