Monitor Biodiesel “Shelf Life” – Test for Bacteria, Fungi and Mold

The use of biodiesel and biodiesel blends is continuing to become more prevalent in the marketplace. Implementation is easy because the fuels work with existing fuel systems with little to no effect on performance.

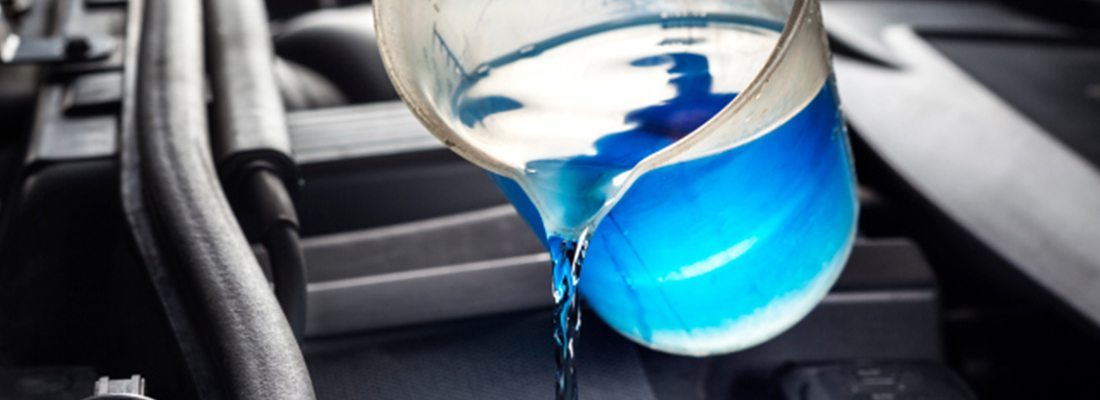

Yet biodiesel fuels are not without problems. They are prone to biological growth and may need special treatment for optimum cold weather performance. Regular testing can help find issues early before they develop and plug fuel filters.

Biodiesel and biodiesel blends are a natural food source for biological growth. Water contamination is a concern for any fuel because, along with corroding the storage tank, water also aids in microbial growth. Testing fuel regularly for bacteria, fungi, and mold, as well as monitoring water content, is recommended to know when treatment is needed.

Testing becomes even more critical as we approach the cooler winter months. Winter temperatures could dip below your fuel’s cloud and pour points which causes filter-plugging wax crystals to form. Biodiesel and biodiesel blends naturally have a higher pour point than #1 and #2 diesel fuel, meaning that they could present cold weather problems sooner. Thankfully, additives are available that can lower cloud point and pour points if a problem is identified.

POLARIS Laboratories® recommends testing bulk fuel tanks every three months to stay on top of filter plugging problems. Regular testing will help you know when to treat your fuel before problems can escalate.

Proven Impact. Proven Uptime. Proven Savings.

Let us prove it to you.

Our Data Analysis Team at POLARIS Laboratories® has

Our Data Analysis Team at POLARIS Laboratories® has

Engine manufacturers are realizing diesel fuel cleanliness can have great impact on overall engine performance. In fact, many are now recommending diesel fuel that does not meet an ISO Cleanliness Code of 18/16/13 should be filtered before introduction to the fuel system. Surprisingly

Engine manufacturers are realizing diesel fuel cleanliness can have great impact on overall engine performance. In fact, many are now recommending diesel fuel that does not meet an ISO Cleanliness Code of 18/16/13 should be filtered before introduction to the fuel system. Surprisingly

The 2015 POLARIS Laboratories Customer Summit has an

The 2015 POLARIS Laboratories Customer Summit has an