Get the Most Value from Your Program: Advanced Testing

Oil Analysis: The First Question

Oil Analysis: The First Question

The first question of any new, or redefined oil analysis program should be, what do I want to achieve from the program? The answer to this question will determine how the program is managed, and more importantly, what testing will be performed on the samples. All samples will receive an element of three groups of testing:

- Wear metal assessment

- Contamination

- Fluid properties

But the depth of testing in these three groups can change, depending on what you want to achieve.

1. Wear Metals

Every oil sample tested will receive an evaluation of wear metals and elements, this is taken as standard in the industry. But the number and type of tests performed in addition to this determine what level of testing is performed, and therefore what level of information you will receive on a sample report. Many companies will go with testing the minimum, so the price per sample is lower.

Does basic testing add significant value to a program or improve reliability?

An example of this could be testing a diesel engine oil without including a base number. This means a true evaluation of the optimum oil drain interval is not possible. Another example would be testing a hydraulic oil with performing an ISO code & particle count so that the laboratory cannot assess the true cleanliness of the fluid. Both of these examples could be considered vital tests in terms of improving reliability and reducing maintenance costs, but are not always included in some basic testing programs.

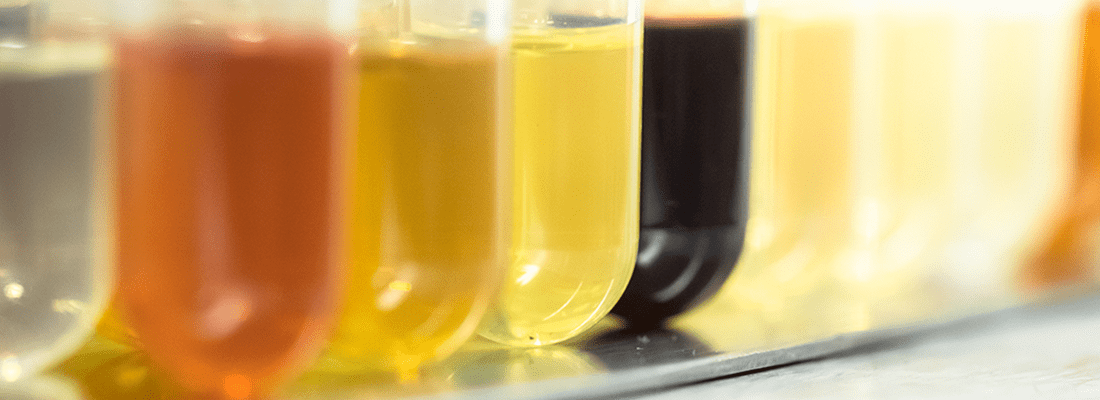

2. Contamination

More importantly, monitoring and reporting actual accurate levels of contaminants present within oil samples is critical because the amount and type of contaminant present will pose a different set of problems at different levels as shown in Tables 1 and 2 below (related to acceptable levels of water contamination in oils). The majority of OEMs provide guidelines for various contaminants and acceptable levels for contamination for their specific systems. Below are a few examples of results of water contamination results and findings from standard testing compared to advanced testing methods.

- Diesel Fuel Dilution

- Stating that diesel fuel dilution is present in engine oil by a simple Flash Point or FTIR evaluation is not an effective method for determining contamination. Diesel dilution condemning limits stated by OEMs can range from 3% to over 5% and therefore an accurate amount of the contaminants present via Gas Chromatography in the oil (diesel in this case) is also now a pre-requisite when looking to monitor contamination levels in samples.

- Water Contamination

-

- Performing a test on an oil sample using the hot plate test method may not always able to detect the exact amount of water within the sample. An advanced test, such as Karl Fischer, would give you more accurate results, especially the lower levels of water.

Table 1

| Water Content Result Reported | Maintenance Action & Decision | |

| Lab 1 result | Water present | Check unit for source of contamination, but as quantity of contaminant is not known, do I change oil? |

| Lab 2 result | Water > 0.2% | Check unit for source of contamination, but as definitive level of contaminant is not known do I change oil? |

| Lab 3 result | Water = 0.35% | Check unit for source of contamination, but as level is below OEM recommendation of 0.45% no oil change required. |

Table 2

| Water Content Result Reported | Maintenance Action & Decision | |

| Lab 1 result | Water present | No problem reported, continue to monitor as normal |

| Lab 2 result | Water <0.1% | No problem reported, continue to monitor as normal |

| Lab 3 result | Water = 432ppm | Check unit for source of contamination and change oil as level is above acceptable level of 350ppm for this application. |

Is it best practice to simply state that ‘water is present’, or would an accurate result in either percentage of parts per million (ppm) add significant value to maintenance decisions?

In addition, when looking at reporting the samples’ cleanliness levels via ISO code & particle count, what aids the customer more, the simple ISO code, or the code complimented with a full breakdown of the number of particles at each micron size?

| ISO CODE |

| 22/19/13 |

| ISO CODE | >4 μm | >6 μm | >10 μm | >14 μm | >21 μm | >38 μm | >70 μm | >100 μm |

| 22/19/13 | 20959 | 3656 | 340 | 73 | 22 | 2 | 0 | 0 |

3. Fluid Properties

The analysis of a lubricants’ overall condition helps determine the future health of equipment and subsequent oil changes or top-ups that may be required. Every laboratory should offer a wide range of fluid condition analysis services based on the machinery that the oil has been sampled from. These tests are a great barometer for the overall condition of the component and the actual lubricant itself. Performing testing on condition is not only an economically viable option, but it should be considered standard for any oil sample. In today’s cost-conscious climate and increased environmentally concerned conditions, extending lubricant life will help decrease costs and protect the environment from early lubricant disposal.

Including Base Number and Acid Number on an engine oil sample and Acid Number alone on industrial oils paired with the utilization of advanced data analysis and interpretation systems makes it possible to make a judgement on how much further an organization can safely extend an oil drain – if the correct parameters are being monitored and the associated recommendations are being followed. These services are not always included in some basic testing programs – this means you could be missing out on significant savings if these are ignored – both financial and environmental.

Any testing is better than none, but upgrading your samples to a more advanced testing will add significant value, proactively improve reliability and save more equipment.

Proven Impact. Proven Uptime. Proven Savings.

Let us prove it to you.

Background on Base Number Testing

Background on Base Number Testing