From the Expert: Effects of Varnish

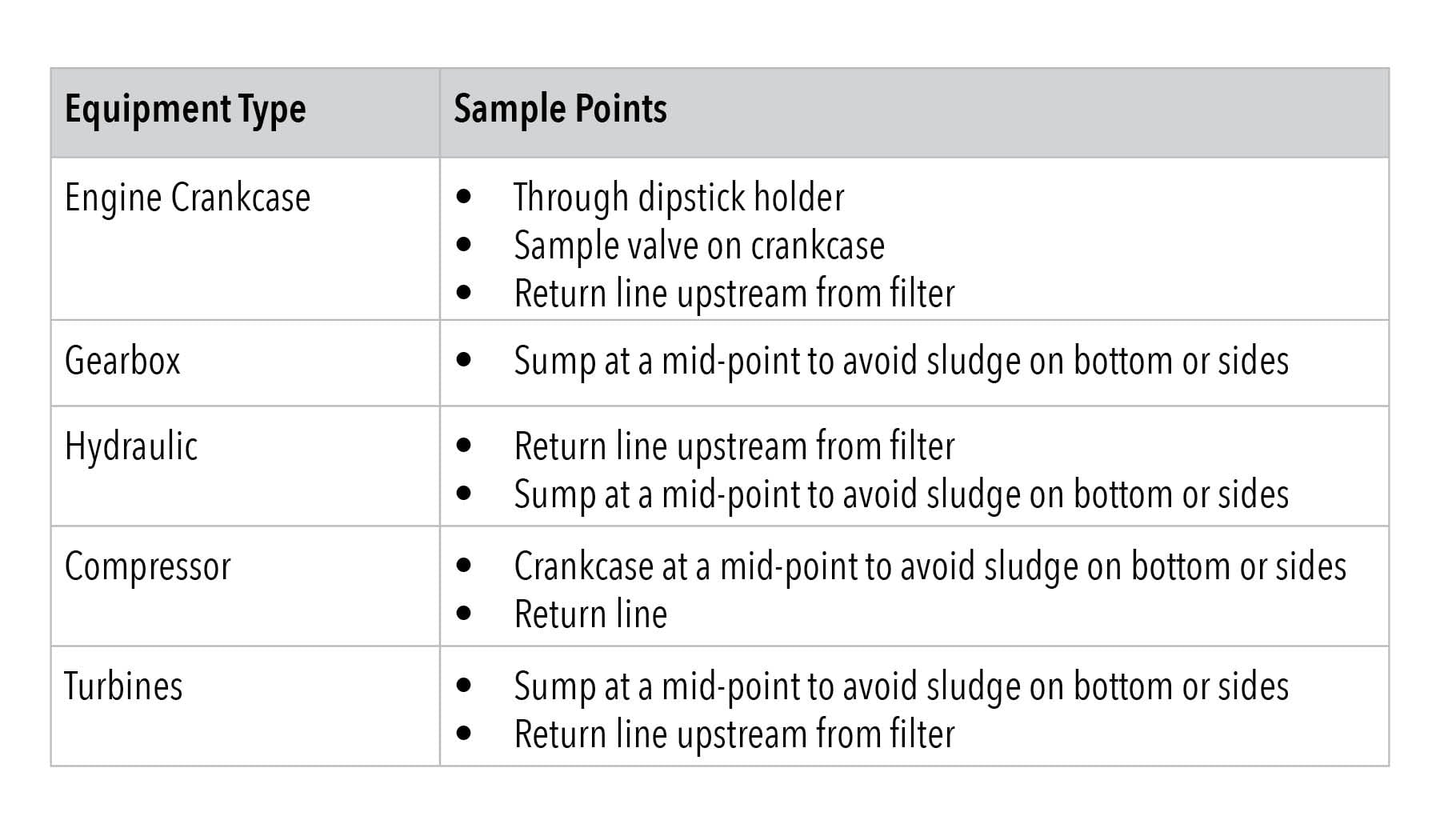

Varnish is a gel-like substance that adheres to metal surfaces and can cause hot spots, increase in machine temperature and can result in filter plugging, micro-dieseling and can cause catastrophic failure. It’s important to test for varnish on turbines, compressors, hydraulics and large circulation and lube systems. We’ve turned to our expert, CLS and OMA I certified Data Analyst, Elaine Hepley, to explore varnish and the Membrane Patch Colorimetry (MPC) test conducted to detect it as well as two other tests that can help identify varnish formation potential.

Varnish is a gel-like substance that adheres to metal surfaces and can cause hot spots, increase in machine temperature and can result in filter plugging, micro-dieseling and can cause catastrophic failure. It’s important to test for varnish on turbines, compressors, hydraulics and large circulation and lube systems. We’ve turned to our expert, CLS and OMA I certified Data Analyst, Elaine Hepley, to explore varnish and the Membrane Patch Colorimetry (MPC) test conducted to detect it as well as two other tests that can help identify varnish formation potential.

- Membrane Patch Colorimetry (MPC) ASTM D7843

- MPC is a test designed to capture any presence of varnish that is soluble with the oil. This test is performed by heating the sample to 60 to 65 degrees Celsius for 23 to 25 hours. The sample is then placed in the dark away from UV light for 68 to 76 hours. After the incubation period, the sample is mixed with Petroleum Ether and stirred for 30 seconds to allow a complete mixture and then filtered onto a 47mm, 0.45-micron-size membrane patch.

- The patch is placed in a location free of dust and heat and air-dried for about 3 hours. Once the patch has been dried, a colorimeter is used to detect the color of the patch and the CIE Lab ΔΕ and L*a*b* calculations are used to report the color of the patch. The color and severity scale is as follows:

- 0-14.99: Severity 0 – Very low potential for varnish formation

- 15-19.99: Severity 1 – Minor potential for varnish formation

- 20-29.99: Severity 2 – Moderate potential for varnish formation

- 30-39.99: Severity 3 – Significant potential for varnish formation. Preventative measures should be taken to stop the continuous formation of varnish

- >40: Severity 4 – Severe and evident formation of varnish in system, and action must be taken to remove varnish.

- The lighter (whiter) the color of the patch, the lower the MPC value and the darker (amber) color of the patch, the higher the MPC value.

- PLEASE NOTE: Gray discoloration of the patch can be attributed to micro-dieseling or static discharge in the filters.

- MPC testing can be performed on turbines and other unit types such as compressors, hydraulics, large circulation and lube systems.

- Linear Sweep Voltammetry (LSV) ASTM D6971

- LSV uses a voltage reading to detect the presence of anti-oxidants amines and phenols. The test is performed using an alcohol/acetone based solution (yellow or green) to help draw out the anti-oxidants from the oil. An electrical current is introduced to the sample and reveals the presence of amines and phenols in a matter of seconds. The results of the used oil are compared to a standard (new lubricant levels) and the differences/changes in the anti-oxidants in percentage are reported.

- Some formulations are composed of amine, phenols or both. Phenols are considered to be the “sacrificial anti-oxidant” when formulated in conjunction with amines. The role that the phenols have is to be the first to deplete. This leaves behind amines to stabilize and keep the potential for varnish at bay.

- That is not to say that phenols are a weak anti-oxidant. In a phenol-only formulation, the phenol is formulated to hold its presence and not deplete as rapidly when formulated with an amine. The same rule would apply to an amine-only formulation. These anti-oxidants help keep the free radical oxides from taking over the system and creating “varnish”. Anti-oxidants help sustain a healthy operational life for the equipment.

- It has been discovered that as these anti-oxidants deplete, the potential for varnish is eminent and action should be taken to help remove the varnish from the system entirely.

- Rotating Pressure Vessel Oxidation Test (RPVOT) ASTM D2272

- RPVOT was designed to measure the oxidation stability of a turbine oil in minutes. The lubricant is placed in a vessel containing a polished copper coil. The vessel is charged with oxygen and then placed in a bath heated to a constant temperature of 150 °C. The vessel rotates while submerged in the bath and will stop once a drop of 25.4 psi is reached from maximum pressure.

- When the test is complete, the RPVOT results are divided by the starting value RPVOT of the new lube to calculate the overall percentage of remaining useful life.

- Calculation %=RVOT test result ÷ RPVOT new lube

- Values of >55% are within the acceptable limits for the method and no action is needed.

- Values of 55-45% are approximately half of the products starting life and sweetening is recommended.

- Values of 44–26% indicate low oxidative stability. The possibility for sludge formation and discoloration is likely, and sweetening the sump is recommended.

- Values of <25% is an indication the oxidative stability is extremely low and change of lubricant is advisable.

- RPVOT testing is essential to for turbine oils this test helps determine when to schedule downtime and maintenance actions.

It is believed that as the antioxidants deplete, there is an increased potential for varnish formation. LSV Ruler testing is recommended to help monitor the antioxidant properties as well as the presence of varnish formation via MPC. As these antioxidants deplete, the presence of varnish forming can be captured on the MPC. These two tests can be used to help correlate any decreases or increases in antioxidants and monitor any changes/improvements with the presence of varnish. The same correlation can be used with RPVOT as the values decrease or are <44% the potential for varnish formation.

Click here for a complete list of testing performed by POLARIS Laboratories®

Proven Impact. Proven Uptime. Proven Savings.

Let us prove it to you.

Building on past feedback from nearly 200 customers across more than 90 companies, the 2018 summit will provide greater variety and depth in the content we share. This is a must-attend for new and returning customers. Specific content will include new insights on:

Building on past feedback from nearly 200 customers across more than 90 companies, the 2018 summit will provide greater variety and depth in the content we share. This is a must-attend for new and returning customers. Specific content will include new insights on:

POLARIS Laboratories® constantly strives to meet our customers needs and expectations. Due to a high number of North American customers with locations throughout Europe, and with increasing shipping costs, in 2013 we decided to establish a laboratory facility in Europe to meet our customers needs on a global scale. This meant reduced shipping costs and much shorter turnaround time for samples for customers.

POLARIS Laboratories® constantly strives to meet our customers needs and expectations. Due to a high number of North American customers with locations throughout Europe, and with increasing shipping costs, in 2013 we decided to establish a laboratory facility in Europe to meet our customers needs on a global scale. This meant reduced shipping costs and much shorter turnaround time for samples for customers.