Kick Off the New Year With A Review of Your Program

As we move into 2018, could you answer these questions?

As we move into 2018, could you answer these questions?

What was the return on your fluid analysis investment in 2017?

Did you meet the goals of your program in 2017?

Beginning a new year is a great time to reevaluate your program and its goals. Outlined below are a few aspects of your fluid analysis program that should be reviewed:

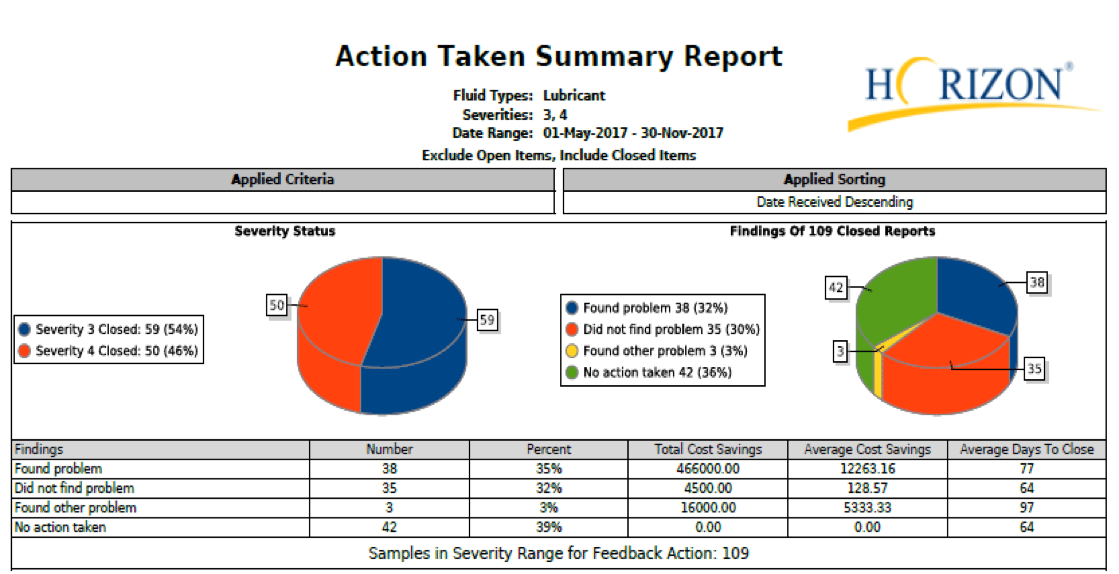

Feedback

Did you provide feedback regarding the accuracy of recommendations in the sample reports? This can be a vital part of a continuous improvement program. For those of you using HORIZON®, you are probably familiar with the “Take Action” function. This is a great place to record your findings and communicate with the data analysis team and let us know if:

- Were the recommendations spot-on?

- Did you find additional issues?

By providing this feedback to the lab, future recommendations will be more detailed and accurate and will start you on the path of continuous improvement. Take a moment to capture the cost savings associated to the report in the “Estimated Savings” field. This will allow you to run a report later to determine the return on investment of your program.

Training

The need for training goes beyond the person who reviews reports or oversees the program. Everyone that handles fluids, repairs equipment, obtains fluid samples or is in any way accountable for the cost of the program should receive formal training on fluid analysis.

- Have you included proper training of personnel as part of your goals for 2018?

- Has everyone in your organization received training?

Transparency

As we kick off 2018, I encourage you to share with all your team members the goals of your fluid analysis program and where you are today in relation to the goals. In order to maximize your current program, continue sharing the progress with your team. You will truly be surprised at how quickly you will obtain your goals when everyone on the team is aware of the progress and realizes what a vital part each of them plays in achieving the goals.

Proven Impact. Proven Uptime. Proven Savings.

Let us prove it to you.