I can’t tell you how many times I’ve heard coolant marketers, OEMs and customers alike say, “There’s no need to test the coolant. We use an ELC.” Extended life coolants, or ELCs, are designed to be more stable, require no supplemental coolant inhibitors and last longer than conventional coolants. However, that doesn’t eliminate the need for coolant testing.

Fluid design won’t prevent or correct many of the problems affecting cooling systems. Mechanical issues, such as combustion gas leaks, air leaks, localized overheating and hotspots or stray electrical grounding, can chemically affect or destroy the coolant and its inhibitors. Once the chemical change occurs, the coolant can attack the metals and components in the system, causing premature failure. Mechanical problems affect conventional and extended life coolants equally, and neither fluid formulation will fix the root cause of the problem.

Coolant contamination is the result of poor maintenance practices and air leaks. Depending on how they affect the pH, contaminants are either going to form acids or alkaline scale in coolants. The acid will corrode or pit cooling system components, degrade hoses and seals and deplete inhibitors and/or additives. Scale affects the oil side of an engine by decreasing the efficiency of heat transfer, which can lead to cracked heads, ring/cylinder wear or bearing wear. Coolants are affected by these problems whether they are conventional or an ELC, and the fluid cannot fix the root cause.

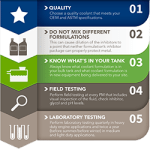

Coolant mixing is another reason why regular fluid analysis is needed for ELCs. With all of the different coolant formulations available today, coolant mixing is a huge issue in the industry. If an incompatible formula makes up more than 25 percent of the total coolant, the inhibitors from both formulas will be too diluted to protect the system, and serious corrosion can occur. Different OEMs use different coolants, so it is easy for fleets with several different brands to mix incompatible formulas together. Even if a fleet maintenance manager stocks the appropriate coolant formulas in the shop, this makes it even easier for maintenance personnel to add the incorrect coolant to a system. This can result in huge maintenance costs from corrosion issues, and this time, the problem is made worse by adding ELC formulas to the spectrum of coolants in stock.

The bottom line is no matter what coolant formula is used, mechanical issues, contaminants and coolant mixing will reduce the life of your fluid and can harm the cooling system and engine. Only regular laboratory coolant analysis can identify issues before damage has occurred. Our ELC test packages will evaluate the life remaining in these specialized formulas, identify if a problem has reduced the life of the coolant and provide maintenance recommendations to help you address the root cause of the problem.

Interested in adding coolant analysis to your maintenance program? Contact us today and we will be in touch with you shortly!

Proven Impact. Proven Uptime. Proven Savings.

Let us prove it to you.

Published June 4, 2014

Our Data Analysis Team at POLARIS Laboratories® has

Our Data Analysis Team at POLARIS Laboratories® has

The 2015 POLARIS Laboratories Customer Summit has an

The 2015 POLARIS Laboratories Customer Summit has an

It’s easy to become overwhelmed when trying to understand the multitude of variation among formulations, but it can actually be broken down quite simply. Take a look at our

It’s easy to become overwhelmed when trying to understand the multitude of variation among formulations, but it can actually be broken down quite simply. Take a look at our