Seeing Proven Savings: One Report at a Time

Fluid analysis is a powerful tool in the preventive maintenance toolbox of many equipment and maintenance managers in industries ranging from construction to aggregates to mining to marine. Efficiently managed programs provide considerable benefits that translate directly into maintenance cost savings for industries who rely on the operation of their equipment.

When operating equipment, it’s inevitable to see some wear as the machine operates overtime. One of the most valuable advantages of fluid analysis is detecting early signs of wear within equipment by analyzing wear particles within the oil.

Saving $80,000 in Engine Replacement Cost

One of POLARIS Laboratories® customers in the Marine industry was able to save the entire replacement of an engine by performing recommended actions on a high severity lubricant analysis sample report. After collecting an oil sample during a break in the oil change schedule, the company’s sample report returned at a high severity. The recommended maintenance action based on the test results and interpretation was to borescope the cylinders, in which the team observed scoring on the cylinder liners.

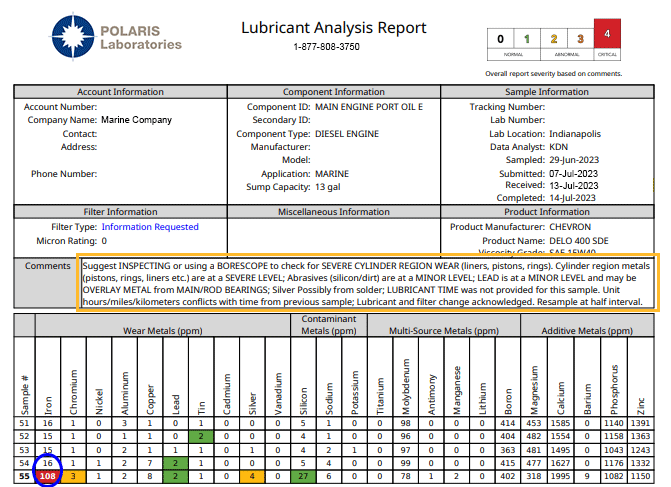

Report showing high levels of iron with a recommendation to check cylinders

While continuing to investigate the concern, it was observed that the bottom of the engine piston crown showed signs of deterioration. After discovering this, a strategic maintenance decision was made to replace all six pistons, liners and connecting rods.

As the company shares this story with POLARIS Laboratories®, it was noted that there were no other condition monitoring indications or alarms that showed there was an engine issue – the concern was only identified based on the test results and recommendations on the lubricant analysis sample report. Without the sample report indicating abnormal wear and suggestion to evaluate the cylinders, the problem would not have been identified and would have led to a total engine loss and $80,000.

Avoiding Lost Production, Downtime and $260,000+ in Engine Loss

For a POLARIS Laboratories® customer in the Aggregates industry, equipment downtime can be detrimental to production, customer satisfaction, labor costs and operations. The company had coolant analysis report came back indicating a high freeze point which, if not addressed, would have caused the engine block to freeze resulting in a complete engine replacement of $135,000 (this does not include the downtime if the asset was out of production for repairs).

In another instance, the company was able to avoid a full axle rebuild that would have cost $50,000 by addressing a simple issue and replacing the oil after a lubricant analysis report came back with results indicating a leak in the axle which had resulted in dirt contamination causing wear.

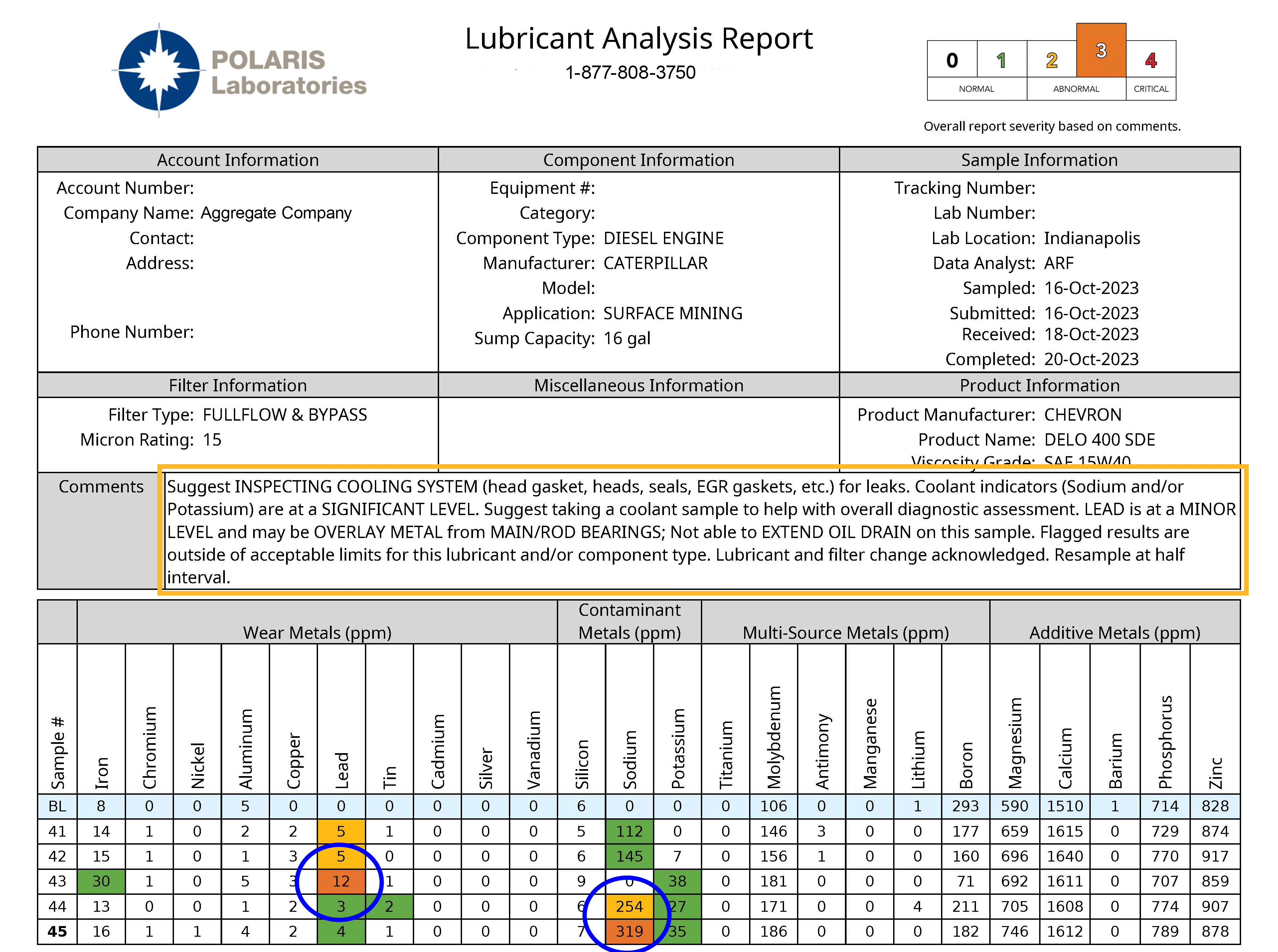

Report showing high levels of sodium with a recommendation to check cooling system for leaks

A very recent equipment save through oil analysis for the company involved receiving a report back that indicated high levels of lead. The team was able to proactively replace the NRS coolers before the engine could experience failure – a failure that would have cost the company $75,000 to repair, plus the additional downtime loss.

Fluid analysis is a proactive, preventive, predictive and cost-effective condition monitoring tool proven to minimize unexpected and un-budgeted maintenance costs by detecting signs of early wear and contamination. Through interpreting test results and maintenance recommendations provided by the data analysts, maintenance and equipment managers can take action before failure even has a chance.

Proven Impact. Proven Uptime. Proven Savings.

Let us prove it to you.

Published November 14, 2023