It’s More Than Fluid Analysis

You’ve made the decision to use POLARIS Laboratories® as your trusted fluid analysis provider, a great start to a successful fluid analysis program. Now are using all the features available? POLARIS Laboratories® provides more than fluid analysis. Learn about how our convenient mobile app can help you manage your program in real time.

You’ve made the decision to use POLARIS Laboratories® as your trusted fluid analysis provider, a great start to a successful fluid analysis program. Now are using all the features available? POLARIS Laboratories® provides more than fluid analysis. Learn about how our convenient mobile app can help you manage your program in real time.

Real-Time Alerts

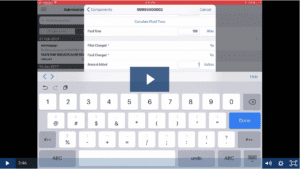

Did you know you can monitor your fluid analysis results, receive real-time alerts on high severity reports and submit online data for your fluid analysis directly from the HORIZON® mobile app?

The HORIZON® mobile app is just another great feature provided by POLARIS Laboratories® to help you manage your fluid analysis program. With customizable settings to receive alerts of the reports that are most vital to the success of your program. Once an alert is received you have the ability to review a summary of the report or with a single click see the full report details.

Submit Your Sample Online

The online sample submission capability of the mobile app is a time saver. Your mechanics now have the ability to select equipment from their phone, scan a QR code with their phone, enter a few fields of information (such as component time and lube time) apply a QR sticker to the bottle and then obtain the sample and mail it directly to the laboratory.No more errors from hand written labels and a much faster process!

But the great features don’t end there. Do you have equipment that you need to transfer from one location to another? You can now keep the data accurate for your fluid analysis program mirrored with physical transfers, and you guessed it, you can do this directly within the mobile app.

Easy Equipment Transfer

What about adding new equipment/components? With just a few fields of information to enter you can add this from the mobile app as well!

At POLARIS Laboratories® we consistently strive to help our customers not just simplify their fluid analysis program but help ensure that your data is always timely and accurate.

The mobile app is free and available for iPhone or Android. Give it a try today, you will not be disappointed.

|

|

Proven Impact. Proven Uptime. Proven Savings.

Let us prove it to you.

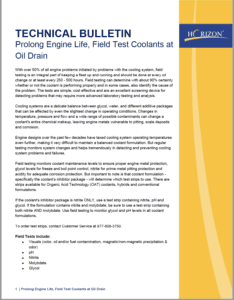

When this occurs the coolant will no longer be able to prevent corrosion of the metals that come in contact with the coolant.

When this occurs the coolant will no longer be able to prevent corrosion of the metals that come in contact with the coolant.