Identifying and Tackling Particle Contamination

The most common cause of equipment failure is particle contamination. This includes external contaminants, such as dirt or sand, as well as the microscopic pieces of metal generated during equipment operation.

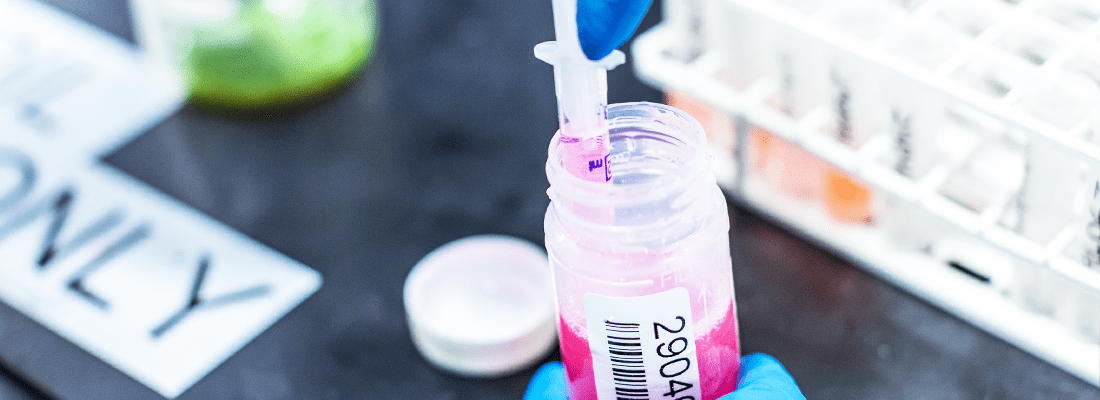

The following tests can further investigate the size and shape of the particles to help your team discover the source of the contamination and assess the damage to the component:

- Atomic Emission Spectroscopy (AES-ICP):

- Elemental analysis (usually performed by an ICP) can identify the most common wear and contamination elements and quantify the concentration of contamination, with a size limitation of particles less than 8 to 10 micron in size, but other typical oil analysis technology can provide additional information of the sizes and type of contamination.

- Particle Count

- Particle count will provide information on the different sizes of particles and their distribution found in the oil but will not determine the type of particles.

- See the different tests available and their testing limits

- Particle Quantifier

- This technology will determine ferrous contamination without a size limitation. And when used in conjunction with AES-ICP when comparing PQ results with ICP results the severity of ferrous particles present can be understood. The ICP will detect the smaller sizes and the Particle Quantifier result greater than ICP would indicate larger particles are present.

Further testing can investigate the size and shape of the particles to help maintenance personnel discover the source of the contamination and assess the damage to the component - See the multiple techniques to quantify particles

- This technology will determine ferrous contamination without a size limitation. And when used in conjunction with AES-ICP when comparing PQ results with ICP results the severity of ferrous particles present can be understood. The ICP will detect the smaller sizes and the Particle Quantifier result greater than ICP would indicate larger particles are present.

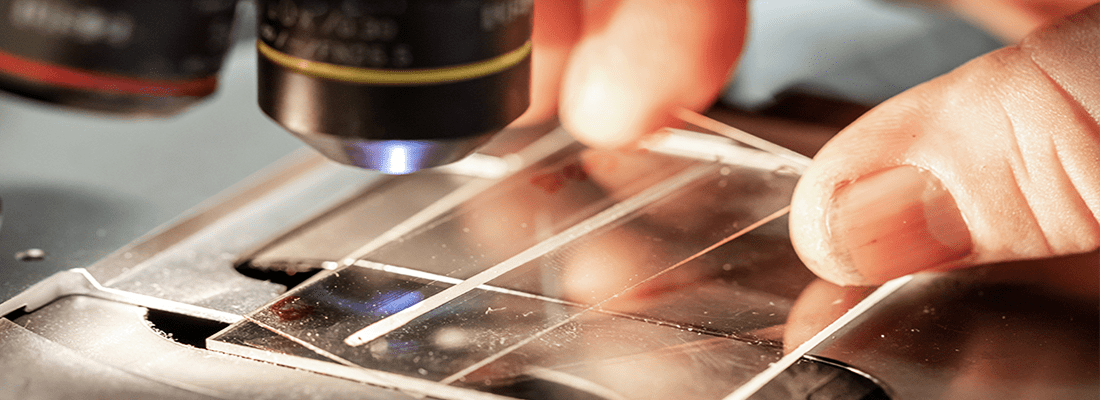

- Microscope Analysis

- Filter debris analysis (FDA), micropatch and analytical ferrography will provide images of specific particles present viewing under a microscope. Pictures of particle contamination, size and type, are included in a separate report with its own severity provided. FDA can evaluate the cause of filter plugging or unexpected breakdown.

- Identify the causes of filter plugging with Filter Debris Analysis

- See how Analytical Ferrography and Micropatch tests can identify the root cause of problems

Each test takes a slightly different approach to this task, and each have their own limitations.

Thankfully, not every method should be included in every circumstance. Recommended tests vary based on type of equipment, equipment criticality, and operating cycles. POLARIS Laboratories® is here to help you choose the best, most cost effective testing for your application. Reach out today for assistance on selecting to correct method for each of your equipment to provide the best information to catch concerns early overall increasing your ROI.

Proven Impact. Proven Uptime. Proven Savings.

Let us prove it to you.

Oil Analysis: The First Question

Oil Analysis: The First Question

Background on Base Number Testing

Background on Base Number Testing