Advancements in Detecting and Measuring Soluble Varnish

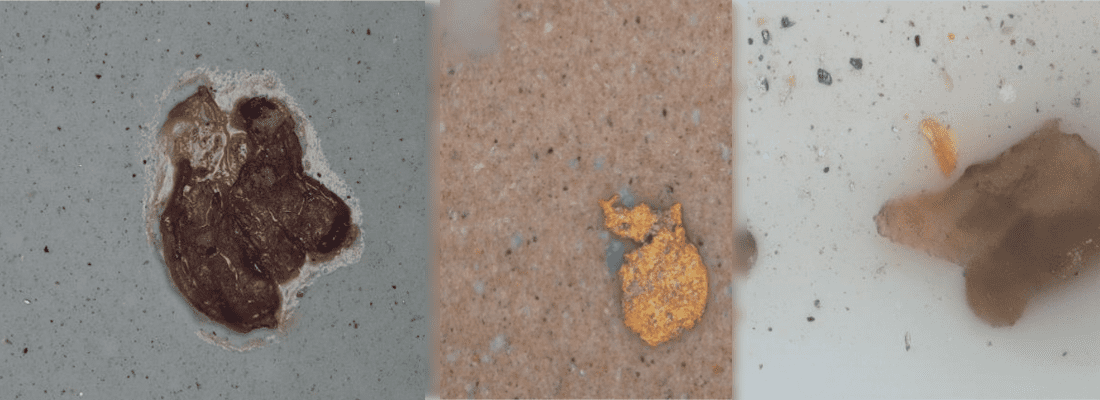

As part of our mission to improve the quality of our interpretation, POLARIS Laboratories® is constantly performing statistical analysis on our test results to evaluate typical parameters and establish thresholds for our tests. We are proud to announce improvements made to our new MPC method, which has the potential to measure soluble varnish in turbines, hydraulics and compressors using R&O formulations. This new method was introduced to our existing MPC method (ASTM D7843) as a tool for customers to more proactively identify and correct their oil’s potential to develop both soluble and insoluble varnish.

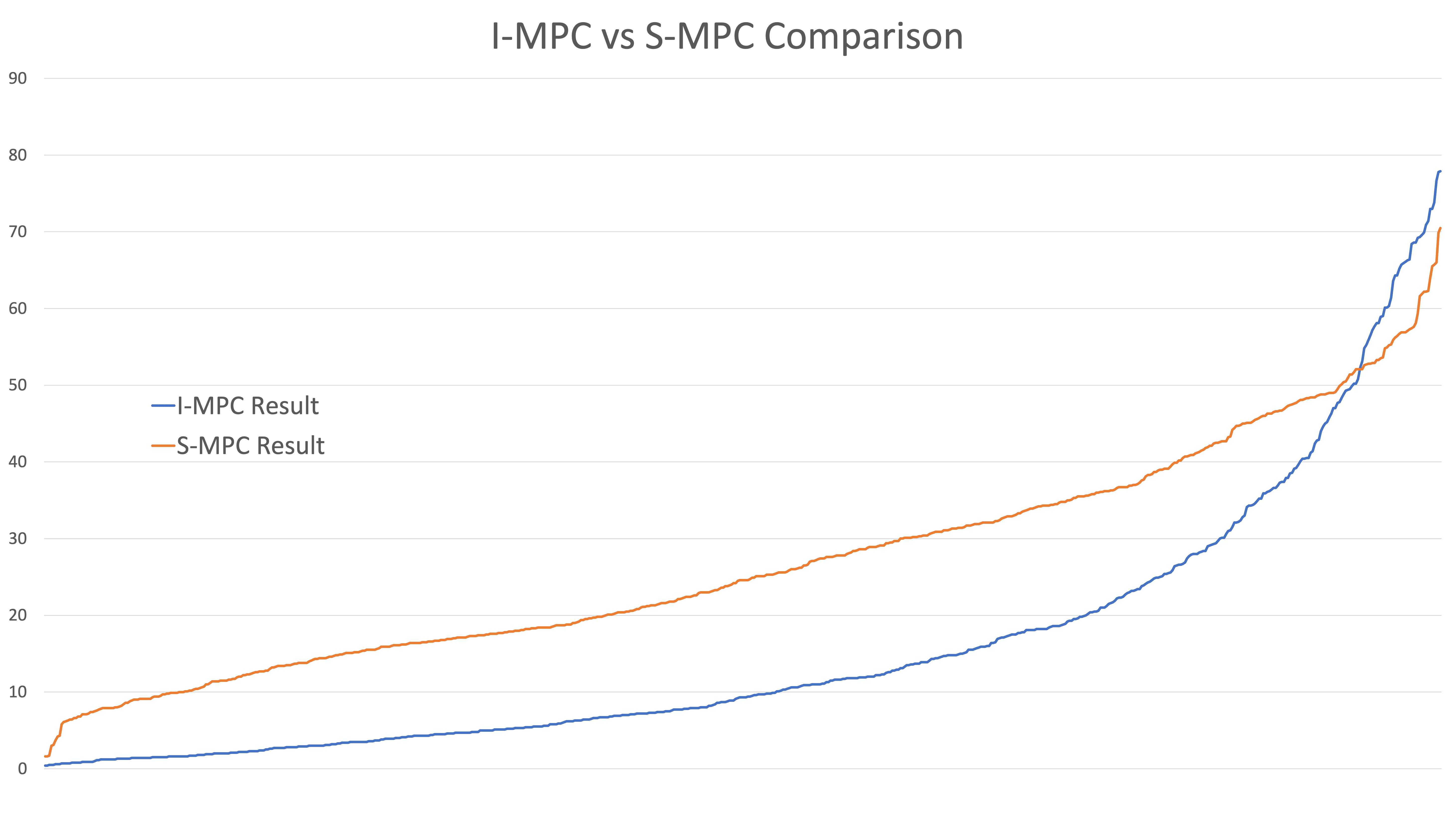

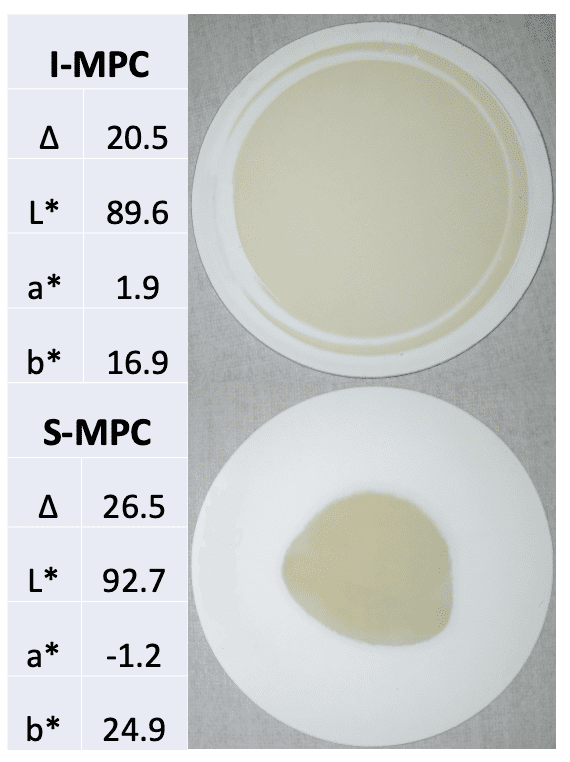

While our new method was introduced with the same severity range as ASTM D7843, we have now collected enough data to confidently establish new limits based on the same statistical methods used for other ASTM tests. Our findings show that the new method tends to produce higher values, and for this reason we will begin considering the results abnormal when they exceed a value of 25, whereas the threshold for the original method is 15.

Along with our new MPC method, we also began reporting L*a*b* values to quantify color value. Our findings show that the L value (black to white) has a strong correlation with our original MPC method, and will now be considered “low” when the value is below 75. Similarly, our findings show that the b* value (yellow) has a strong correlation with the new MPC method, so this value will now be considered “high” when it exceeds a value of 35.

As with any other test that has been introduced, we are working to make improvements and understand factors that will influence the results. The new MPC method has the potential to measure soluble varnish, however there are many other variables that can influence the results. We will now start listing these variables on the report if the new MPC method is high, and will not recommend that any action be taken unless results for the original method are high as well.

POLARIS Laboratories® strives to continually improve our methods and interpretation of the analysis conducted on fluid samples to assist our customers catch varnish contamination sooner, saving more equipment and improving reliability.

Proven Impact. Proven Uptime. Proven Savings.

Let us prove it to you.

Published July 28, 2023

provide the laboratory with equipment, component, manufacturer and fluid information.

provide the laboratory with equipment, component, manufacturer and fluid information.